Welcome to Mondince Bike - A well-known factory specialized in produce carbon bike frame and other parts since 2007.

Understanding the Basics of Carbon Fiber

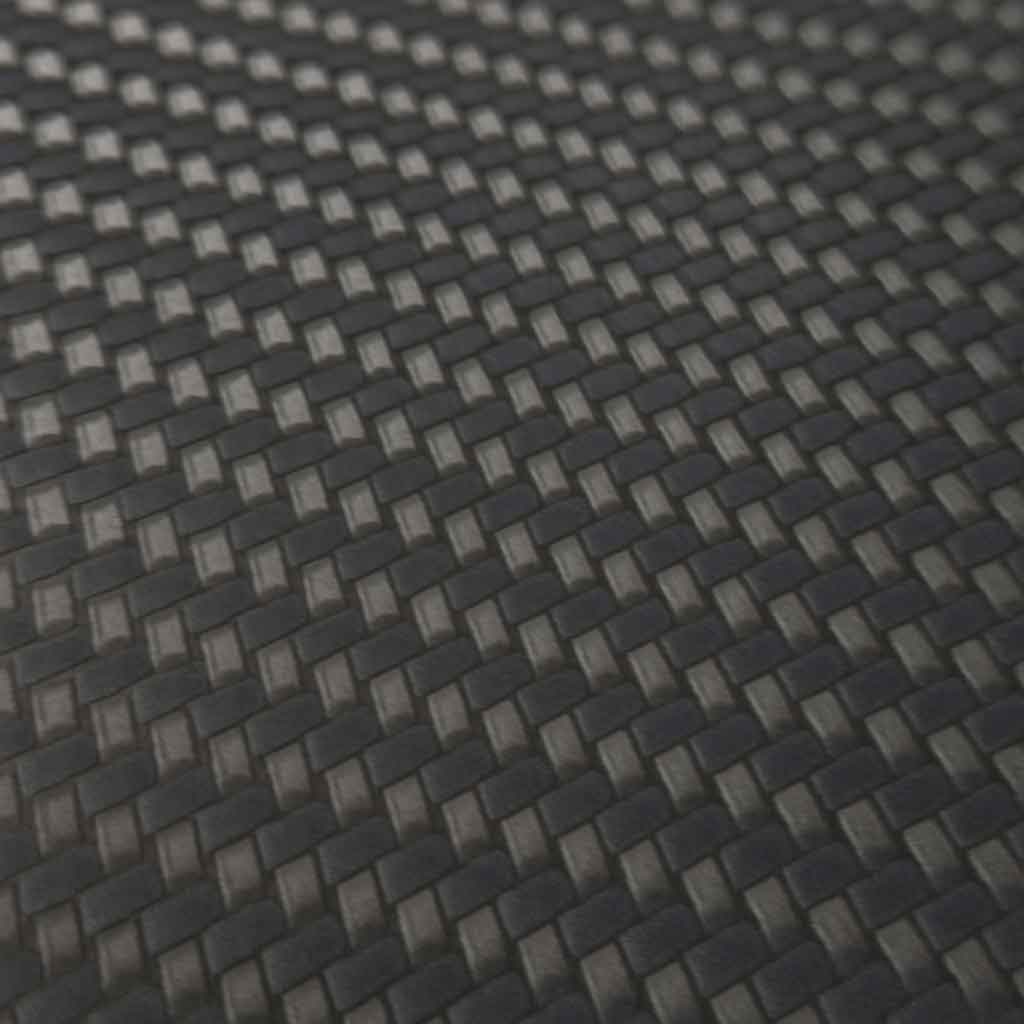

Carbon fiber is a material known for its exceptional strength and lightweight properties, making it a favorite among engineers and designers alike. This versatile material is employed across various industries, ranging from aerospace to sports equipment, due to its unique capabilities. Understanding the fundamental characteristics of carbon fiber, its composition, and why it holds such value is crucial for industries looking to innovate and optimize their products. In this article, we will delve into the composition, properties, and applications of carbon fiber, highlighting what makes it an indispensable material in modern technology.

What Is Carbon Fiber?

Carbon fiber, sometimes referred to as carbon fibre, consists of carbon atoms bonded together in a crystalline formation. These fibers are significantly thinner than a human hair, yet they possess remarkable strength and rigidity. The material's robust nature is attributed to the strong covalent bonds between carbon atoms, which contribute to its exceptional tensile strength. Additionally, carbon fiber's crystalline structure provides it with a high degree of stiffness, making it a preferred choice for applications demanding both strength and weight efficiency.

Is Carbon Fiber a Metal?

Contrary to some assumptions, carbon fiber is not a metal. It is a composite material derived from organic polymers, specifically polyacrylonitrile (PAN) or petroleum pitch. Unlike metals, carbon fiber does not conduct electricity in its pure form, nor does it corrode, which adds to its appeal in environments where metal oxidation is a concern. The unique structure of carbon fiber imparts characteristics that are distinct from metals, such as reduced weight and higher tensile strength, making it advantageous for uses where traditional metals might falter. These properties make carbon fiber a critical component in sectors that prioritize performance and durability over material cost.

Carbon Fiber Composition and Structure

Carbon fiber is composed of long strands of carbon atoms, which are bonded together in microscopic crystals that align parallel to the fiber's long axis. This alignment is key to the material's strength, as it allows the load to be distributed evenly across the fibers, enhancing their ability to withstand stress. The parallel arrangement of the crystals in carbon fiber is what makes it incredibly strong for its size, enabling the production of lightweight yet robust structures.

Carbon Fiber Chemical Structure

The chemical structure of carbon fiber involves carbon atoms arranged in a hexagonal pattern, similar to graphite. This arrangement is known as a graphitic structure and is responsible for the fiber's impressive strength and stiffness. The hexagonal configuration allows for tight packing of atoms, which maximizes the number of covalent bonds per unit area, thereby increasing the material's strength. This structure also facilitates the high thermal stability of carbon fiber, making it resistant to deformation at elevated temperatures—a property beneficial in high-performance applications.

Key Properties of Carbon Fiber

Carbon fiber is renowned for its outstanding material properties, which make it a sought-after choice for a variety of applications. These properties are a result of its unique composition and structure, which confer several advantages over traditional materials.

Strength and Tensile Modulus

- Carbon Fiber Tensile Strength: Carbon fiber is celebrated for its high tensile strength, which allows it to endure significant stress without breaking. This property is vital for applications requiring durability, such as in the construction of bridges or in the automotive industry.

- Ultimate Tensile Strength: The ultimate tensile strength of carbon fiber is the maximum stress it can endure while being stretched before breaking. This makes it suitable for high-stress applications, such as aerospace components where materials must withstand extreme forces.

- Tensile Modulus of Carbon Fiber: This measures the fiber's stiffness or resistance to being deformed elastically. A higher tensile modulus indicates a stiffer material, which is beneficial for applications needing precise control and minimal deformation under load, such as in precision machinery.

Density and Weight

- Density of Carbon Fiber: Known for its low density, carbon fiber is much lighter than metals like steel or aluminum. This characteristic is crucial in industries where weight reduction is a priority, such as in the design of aircraft or racing cars.

- Carbon Fibre Composite Density: When combined with other materials to form composites, carbon fiber retains its lightweight properties. This makes it a preferred choice for the automotive and aerospace industries, where reducing the weight of vehicles can lead to significant improvements in fuel efficiency and performance.

Elastic Modulus and Yield Strength

- Carbon Fiber Elastic Modulus: The elastic modulus indicates the ability of carbon fiber to return to its original shape after deformation. A high elastic modulus means the material is very rigid, which is beneficial in structural applications where maintaining shape under stress is critical.

- Yield Strength of Carbon Fibre: Yield strength is the stress at which a material begins to deform plastically. Carbon fiber has a high yield strength, meaning it can withstand considerable stress without permanent deformation. This property is particularly important in safety-critical applications, such as in the construction of protective gear or automotive crash structures.

Applications of Carbon Fiber

Carbon fiber's unique properties make it suitable for a wide range of applications, offering solutions that traditional materials cannot match. Its versatility and performance have made it a cornerstone in several key industries.

Aerospace and Automotive Industries

In the aerospace and automotive sectors, reducing weight is crucial for improving fuel efficiency and performance. Carbon fiber composites are extensively used in aircraft and car manufacturing to reduce weight without compromising strength. In aerospace, the material's lightweight nature allows for increased payloads and improved fuel efficiency. In the automotive industry, carbon fiber contributes to faster acceleration, improved handling, and reduced emissions due to its lightweight nature.

Sports Equipment

From bicycles to golf clubs, carbon fiber is used extensively in sports equipment. Its lightweight nature allows athletes to perform better by reducing fatigue and increasing speed. In cycling, carbon fiber frames are favored for their strength and weight, providing a competitive edge. Similarly, in racquet sports, carbon fiber allows for the creation of equipment that is both strong and easy to maneuver, enhancing player performance.

Other Uses

Beyond aerospace and sports, carbon fiber is used in medical equipment, wind turbine blades, and even musical instruments due to its favorable material properties. In the medical field, carbon fiber's lightweight and non-corrosive nature make it ideal for prosthetics and surgical instruments. Wind turbines benefit from the material's strength-to-weight ratio, allowing for larger, more efficient blades. In musical instruments, carbon fiber provides durability and resistance to environmental changes, ensuring consistent performance.

Carbon Fiber vs. Other Materials

When compared to traditional materials like steel or aluminum, carbon fiber offers several advantages that make it an attractive option for many applications.

- Strength to Weight Ratio: Carbon fiber has a superior strength-to-weight ratio, making it ideal for applications where both strength and weight are critical. This is particularly important in industries such as aerospace and automotive, where performance and efficiency are closely linked to material properties.

- Corrosion Resistance: Unlike metals, carbon fiber does not corrode, making it suitable for harsh environments where metal components might deteriorate over time. This property extends the lifespan of products and reduces maintenance costs.

- Thermal Expansion: Carbon fiber has low thermal expansion, which means it does not expand or contract significantly with temperature changes. This stability is advantageous in precision applications where dimensional changes could affect performance or safety.

Challenges and Considerations

While carbon fiber is an excellent material, it does have some challenges that must be addressed to maximize its potential.

- Cost: Carbon fiber is more expensive than many traditional materials, which can limit its use in cost-sensitive applications. The high cost is primarily due to the complex manufacturing process and the quality of raw materials required.

- Manufacturing Complexity: Producing carbon fiber composites can be complex and requires specialized equipment and expertise. This complexity can increase production time and costs, making it challenging to integrate carbon fiber into mass-market products.

Future of Carbon Fiber

The future looks promising for carbon fiber as advancements in technology continue to reduce costs and improve manufacturing techniques. As industries seek more sustainable and efficient materials, carbon fiber's role is expected to expand further. Innovations in production methods, such as automated layup processes and recycling techniques, are likely to make carbon fiber more accessible and eco-friendly. As demand for high-performance materials grows, carbon fiber will continue to play a crucial role in shaping the future of engineering and design.

by Wolfgang Rottmann (https://unsplash.com/@quadratmedia)

Conclusion

Carbon fiber is a remarkable material with a unique combination of properties that make it invaluable in many fields. Understanding its characteristics and applications can help industries leverage its strengths for innovative solutions. Whether in aerospace, sports, or beyond, carbon fiber continues to shape the future of material science. As technology advances, the potential applications for carbon fiber are only set to increase, paving the way for new innovations and possibilities.