Welcome to Mondince Bike - A well-known factory specialized in produce carbon bike frame and other parts since 2007.

How Carbon Fiber is Made and Used

Carbon fiber is a fascinating material that has captured the attention of engineers, designers, and manufacturers across numerous industries. Known for its impressive strength-to-weight ratio, carbon fiber offers incredible versatility, making it a popular choice for a wide range of applications. In this article, we'll explore how carbon fiber is made, its unique properties, and the various ways it is used.

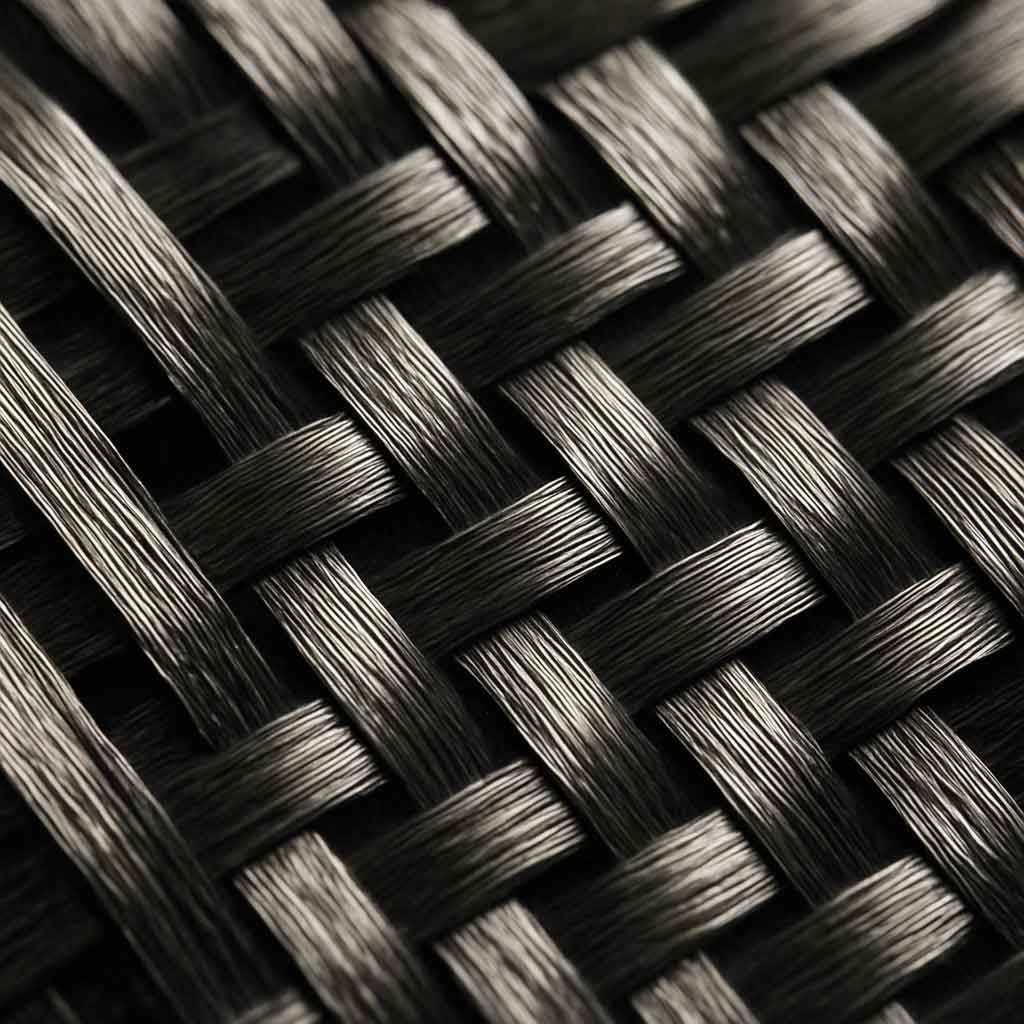

Carbon fiber is a material composed of thin, strong crystalline filaments of carbon. These filaments are incredibly thin, often with a diameter of about 5 to 10 micrometers. When bundled together, these fibers create a fabric-like material that can be used in a variety of ways. But what makes carbon fiber so special? Let's take a closer look at its characteristics.

Carbon Fiber Characteristics

Carbon fiber is known for several key properties that set it apart from other materials:

- Strength: Carbon fiber has a high breaking strength, meaning it can withstand significant force without breaking.

- Lightweight: Despite its strength, carbon fiber is extremely lightweight, making it ideal for applications where weight reduction is crucial.

- Stiffness: It has a high tensile modulus, which means it is very stiff and resistant to bending.

- Corrosion Resistance: Carbon fiber is chemically resistant, so it won't rust or corrode.

- Heat Resistance: It can withstand high temperatures without losing its properties.

- Electrical Conductivity: Carbon fiber is conductive, though not as much as metals.

These properties make carbon fiber an attractive option for many industries, from aerospace to sports equipment.

How is Carbon Fiber Made?

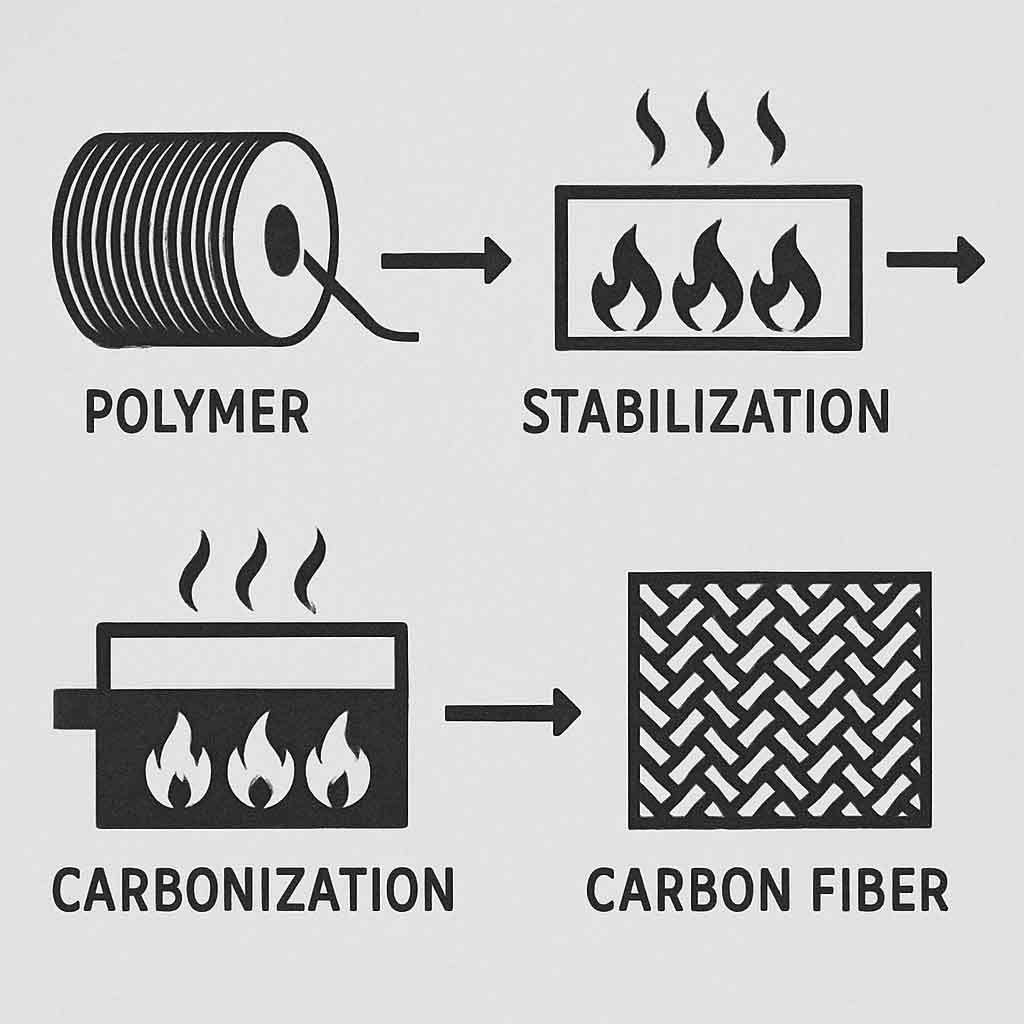

The production of carbon fiber involves several steps, transforming raw materials into the finished product. Here's a simplified overview of the process:

1. Raw Materials

The primary raw material for carbon fiber is a precursor, typically made from polyacrylonitrile (PAN) or pitch. These materials are chosen for their high carbon content, which is essential for creating strong carbon fibers.

2. Stabilization

The precursor fibers are first stabilized by heating them in air at a low temperature. This process causes chemical changes that prepare the fibers for carbonization.

3. Carbonization

In the carbonization phase, the stabilized fibers are heated to very high temperatures (around 1000-3000°C) in an inert atmosphere. This process removes non-carbon atoms, leaving behind long chains of carbon atoms that form the characteristic strong crystalline structure.

4. Surface Treatment

After carbonization, the fibers undergo surface treatment to improve bonding with resins. This step is crucial for applications where carbon fiber is used as a composite material.

5. Sizing

Finally, a protective sizing agent is applied to the fibers. This helps protect them during handling and improves compatibility with other materials.

These steps result in the production of carbon fiber strands, which can be woven into fabrics or combined with resins to form composite materials.

Properties of Carbon Fiber

Carbon fiber's unique properties make it suitable for various applications. Let's explore some of its key material properties:

Strength and Stiffness

Carbon fiber's ultimate tensile strength and yield strength are among its most notable attributes. It can bear heavy loads while maintaining its shape, making it ideal for structural applications.

Density

With a density significantly lower than metals, carbon fiber is perfect for industries where weight reduction is essential, such as aerospace and automotive sectors.

Elastic Modulus

The elastic modulus of carbon fiber measures its stiffness, which is critical for applications requiring rigidity.

Chemical Structure

Carbon fiber's chemical structure contributes to its corrosion resistance, making it a reliable choice for environments where exposure to moisture or chemicals is a concern.

How is Carbon Fiber Used?

by Isuru Ranasinha (https://unsplash.com/@isuru18)

Carbon fiber is used in a wide variety of applications due to its unique properties. Here are some of the most common uses:

Aerospace and Aviation

In the aerospace industry, carbon fiber is used for aircraft components, such as wings, fuselages, and interior parts. Its lightweight nature helps reduce fuel consumption and improve overall efficiency.

Automotive

The automotive industry utilizes carbon fiber for high-performance vehicles, where reducing weight can enhance speed and fuel efficiency. Components such as hoods, roofs, and spoilers are often made from carbon fiber.

Sports Equipment

Carbon fiber is popular in sports equipment, including bicycles, tennis rackets, and golf clubs. Its strength and lightweight properties enhance performance and durability.

Wind Energy

In the renewable energy sector, carbon fiber is used for wind turbine blades. Its strength and stiffness allow for longer blades, which can capture more energy.

Medical Devices

Carbon fiber is also used in the medical field for prosthetics and orthopedic devices. Its lightweight and strong nature make it comfortable for patients while providing necessary support.

Construction

Carbon fiber is finding its way into construction, where it's used to reinforce concrete and other structures. Its corrosion resistance and strength make it an attractive option for infrastructure projects.

Conclusion

Carbon fiber is an exceptional material with a wide range of applications. Its combination of strength, lightweight properties, and resistance to environmental factors makes it a valuable asset across various industries. As technology advances, the use of carbon fiber is likely to expand even further, offering innovative solutions to modern challenges.

In summary, whether in the sky, on the road, or in everyday products, carbon fiber continues to shape the future of materials science. Its unique properties and versatility ensure it remains a critical component in the development of new technologies and solutions.