Welcome to Mondince Bike - A well-known factory specialized in produce carbon bike frame and other parts since 2007.

what carbon fiber is made of

Carbon fiber is a material that has revolutionized many industries. Its unique properties make it a favorite in aerospace, automotive, and sports equipment. But what exactly is carbon fiber made of?

Understanding carbon fiber composition is key to appreciating its benefits. It primarily consists of carbon atoms arranged in a crystalline structure. This arrangement gives carbon fiber its remarkable strength and lightness.

The production process involves transforming raw materials like polyacrylonitrile into carbon fiber. This process is complex and energy-intensive, requiring precise control. Despite the challenges, the demand for carbon fiber continues to grow due to its unmatched performance.

What Is Carbon Fiber?

Carbon fiber is a material that consists of thin fibers, mainly composed of carbon atoms. These atoms are bonded together in a pattern that results in a material incredibly strong yet lightweight. Its properties make it essential for industries that require durability without added weight.

The fibers usually measure between five to ten micrometers in diameter. Despite their small size, they offer significant benefits over traditional materials like steel or aluminum. This makes them highly sought after.

Key characteristics of carbon fiber include:

- High tensile strength

- Low weight

- Resistance to corrosion

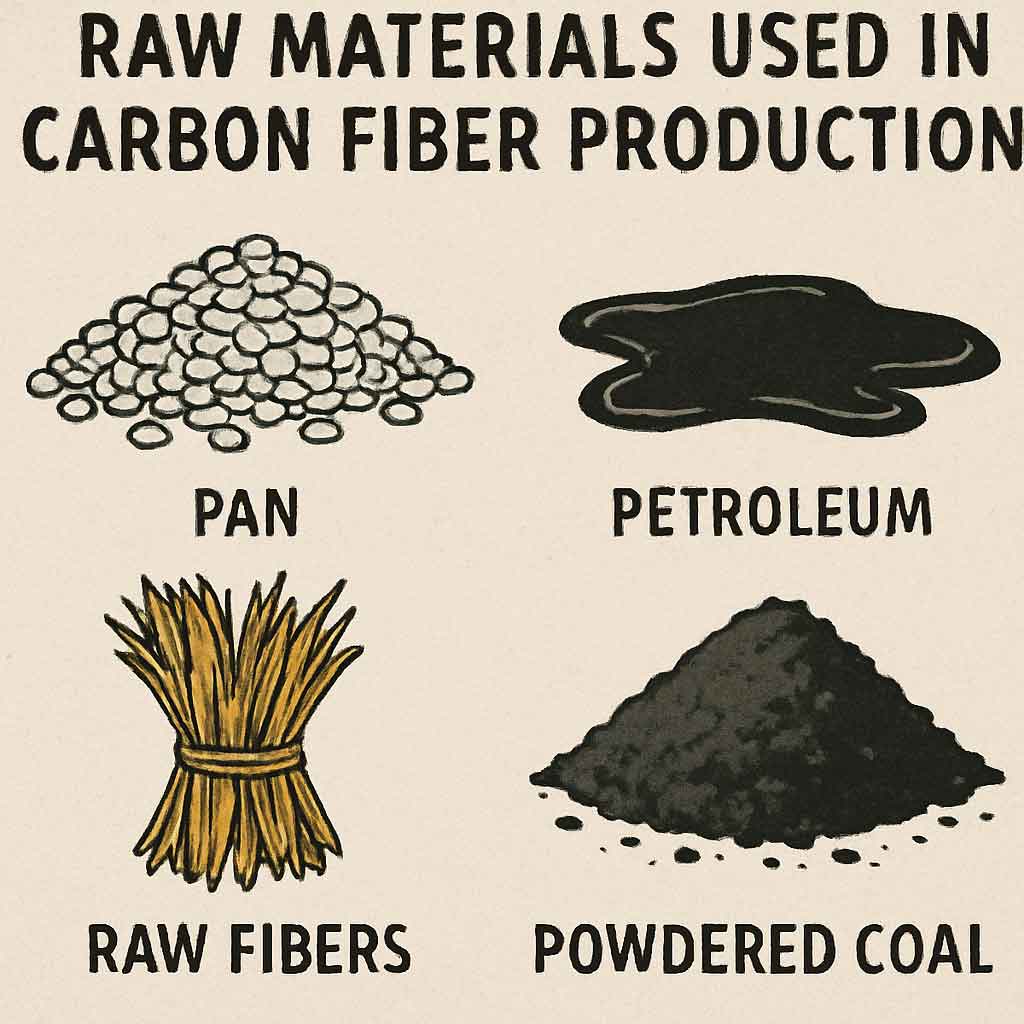

The Raw Materials: What Goes Into Carbon Fiber

The primary raw material for carbon fiber production is polyacrylonitrile, commonly known as PAN. This polymer serves as the most popular precursor due to its stable carbon structure.

Aside from PAN, other materials like pitch and rayon can be used, although they are less common. Each precursor offers unique attributes that influence the properties of the resulting carbon fiber.

The choice of precursor materials affects the carbon fiber's quality, cost, and application. For industrial purposes, PAN remains the top choice because of its reliability and efficiency.

Key raw materials include:

- Polyacrylonitrile (PAN)

- Pitch

- Rayon

These materials undergo a detailed and energy-intensive process to become high-performance carbon fibers.

The Carbon Fiber Manufacturing Process

The manufacture of carbon fiber is intricate, demanding precise control over multiple stages. Initially, the precursor material is spun into fine threads. This process transforms it into a workable fiber ready for further treatment.

The next step is stabilization, where fibers are chemically altered by heating them in the air. This treatment changes the fibers into a stable, non-melting state.

Following stabilization, carbonization occurs in an inert atmosphere, involving high temperatures. This phase aligns the carbon atoms and removes non-carbon elements, enhancing fiber properties.

The surface treatment enhances bonding between fibers and resins, crucial for composite strength. Finally, the fibers are coated with a protective layer to maintain quality.

Key steps in the process:

- Spinning

- Stabilization

- Carbonization

- Surface treatment

- Coating

This detailed manufacturing sequence ensures the production of robust and versatile carbon fibers.

by Mick Haupt (https://unsplash.com/@rocinante_11)

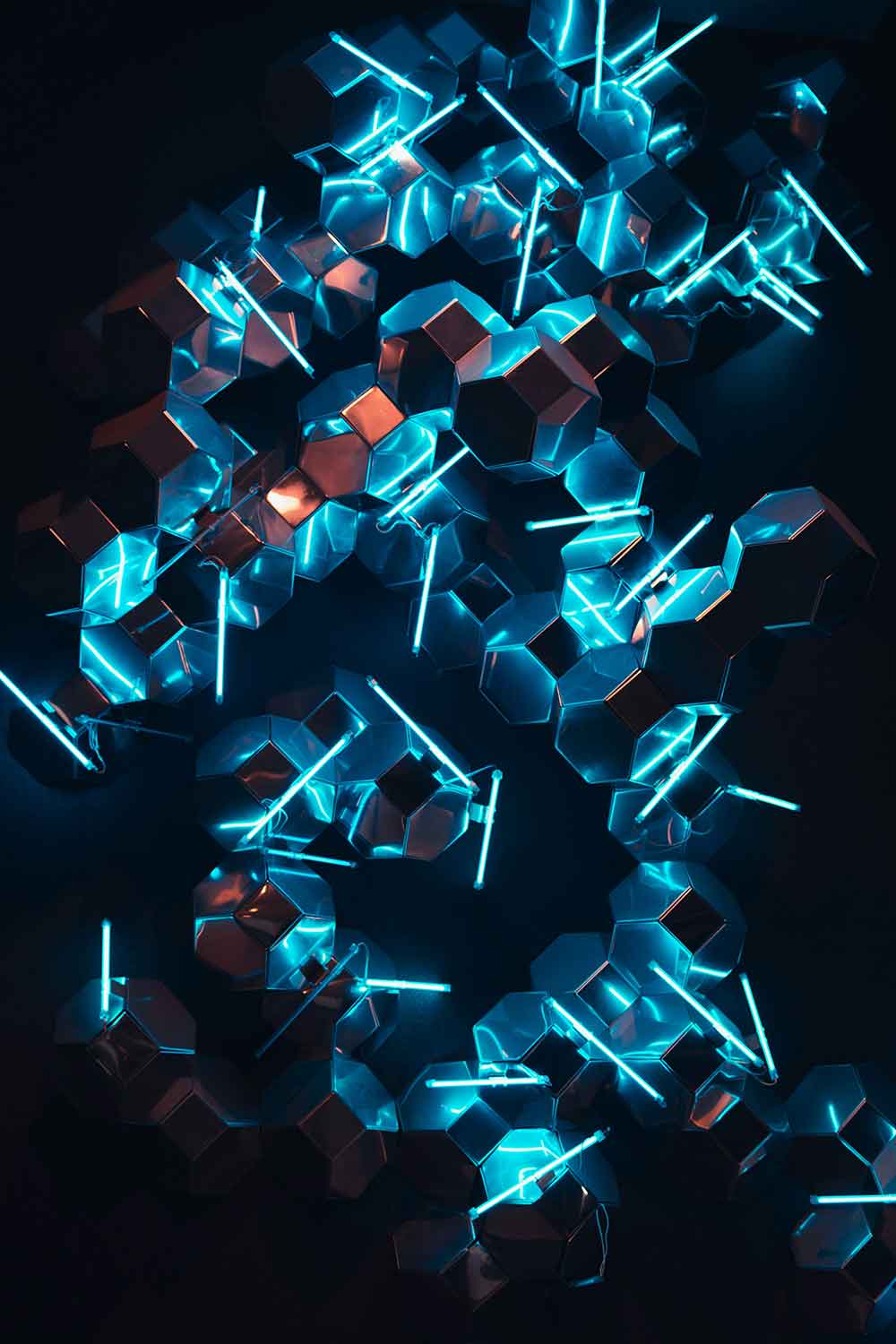

Carbon Fiber Composition: Atomic and Molecular Structure

Carbon fiber's unique strength lies in its atomic structure. The fibers are predominantly made of carbon atoms. These atoms are bonded tightly in a crystalline pattern, contributing to the material's high strength.

The alignment of carbon atoms is crucial. In carbon fiber, atoms arrange in long, thin sheets. These sheets, or graphene layers, stack together forming the fibers.

The molecular structure influences key properties. High tensile strength, low density, and thermal stability are direct results. Understanding this composition is essential for tailoring carbon fibers for specific uses.

Key characteristics of carbon fiber:

- Crystalline atomic structure

- Strong covalent bonding

- Layered molecular arrangement

by Maximalfocus (https://unsplash.com/@maximalfocus)

Key Carbon Fiber Properties

Carbon fiber is renowned for its remarkable properties. These characteristics make it a sought-after material in many industries. Strength and weight play pivotal roles in its appeal.

One standout feature is its high strength-to-weight ratio. This property surpasses most traditional materials. It enables designs that are both robust and light.

Another advantage is its exceptional tensile strength. Carbon fiber can withstand significant stress without stretching or breaking. This capability makes it ideal for demanding engineering applications.

Additionally, carbon fiber exhibits impressive thermal stability. It remains stable under extreme temperatures. This thermal resilience expands its usage across different environments.

Furthermore, carbon fiber is resistant to chemical corrosion. It maintains its integrity even when exposed to harsh chemicals. This durability is essential in many industrial settings.

Significant properties include:

- High strength-to-weight ratio

- Exceptional tensile strength

Additional advantages are:

- Outstanding thermal stability

- Resistance to chemical corrosion

by Émile Dionne (https://unsplash.com/@ashache_)

Common Carbon Fiber Materials and Composites

Carbon fiber materials are versatile, allowing for various applications. They are frequently combined with resins to create composites. This combination enhances performance and adaptability.

The most common precursor for carbon fibers is polyacrylonitrile (PAN). However, alternatives like pitch and rayon are also used. Each precursor offers different benefits and characteristics.

Composites made with carbon fibers are tailored for specific functions. Adjusting the fiber orientation and resin type can optimize performance. This customization is key in achieving desired outcomes.

Types of carbon fiber materials:

- Polyacrylonitrile (PAN)

- Pitch

- Rayon

by Rick Rothenberg (https://unsplash.com/@rick_rothenberg)

Applications of Carbon Fiber

Carbon fiber's unique properties make it invaluable in various fields. Its high strength-to-weight ratio is crucial in aerospace, reducing fuel usage while withstanding high stress.

In the automotive industry, carbon fiber helps to improve vehicle efficiency. Lightweight components boost performance and reduce emissions.

Sports equipment manufacturers also benefit from carbon fiber. Bicycles, tennis rackets, and golf clubs made with carbon fiber enhance player performance through durability and precision.

Key applications of carbon fiber:

- Aerospace components

- Automotive parts

- Sports equipment

by Kotryna Juskaite (https://unsplash.com/@kotrynajuskaite)

Challenges, Cost, and Sustainability

Carbon fiber offers many benefits, but its high cost poses a challenge. Producing carbon fiber is energy-intensive, limiting its use in consumer products.

Another significant challenge is recycling carbon fiber. Unlike metals, recycling carbon fiber is complex and requires specialized processes.

Sustainability efforts focus on reducing production costs and improving recycling methods. Innovations aim to make carbon fiber more environmentally friendly.

Challenges in carbon fiber production:

- High production costs

- Recycling difficulties

- Energy-intensive processes

by Leah Storme (https://unsplash.com/@leah_stormy_storme)

The Future of Carbon Fiber Materials

The future of carbon fiber looks promising with ongoing research and development. Innovations aim to make production more efficient and cost-effective.

Emerging technologies are enhancing carbon fiber properties. These advances will expand applications in various industries, improving sustainability and functionality.

Future trends to watch:

- Improved production techniques

- Advances in recycling methods

- New applications in emerging markets

As these trends unfold, carbon fiber's role in technology and sustainability is set to grow significantly.