Welcome to Mondince Bike - A well-known factory specialized in produce carbon bike frame and other parts since 2007.

Benefits of Using Carbon Fiber Sheets

Carbon fiber sheets have become a cornerstone in various industries, celebrated for their remarkable strength-to-weight ratio and unparalleled versatility. Whether you're delving into aerospace, pioneering automotive advancements, or innovating in sporting goods, carbon fiber sheets offer a plethora of advantages. This article delves into the myriad benefits of carbon fiber sheets, explores the diverse types available, and guides you on where to purchase them.

Carbon fiber sheets are engineered using fine layers of carbon fibers, intricately woven to create a fabric-like texture. These fibers are subsequently bonded with a resin, forming a composite that is both lightweight and extraordinarily strong. This unique blend results in a product that significantly outperforms metals like steel and aluminum in terms of weight, while still offering comparable strength and durability.

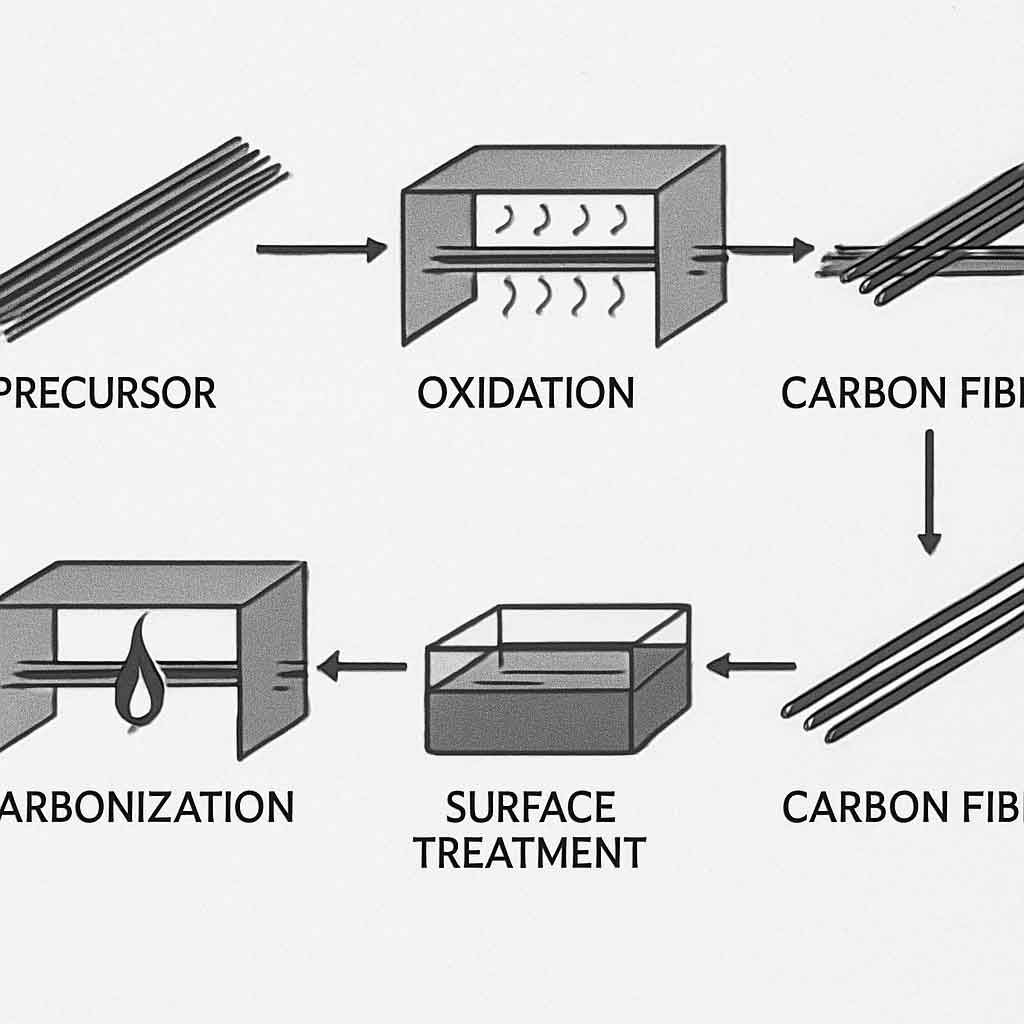

The creation of carbon fiber sheets begins with the production of carbon fibers, which are derived from organic polymers. The fibers are then woven into sheets, which are subsequently impregnated with resin. This process not only enhances the strength and durability of the sheets but also allows for customization in terms of thickness and flexibility.

When it comes to comparing carbon fiber sheets with traditional materials like steel or aluminum, the differences are striking. Carbon fiber offers a superior strength-to-weight ratio, making it ideal for applications where weight reduction is crucial. Additionally, its resistance to corrosion and thermal stability makes it a more durable option in harsh environments.

In an era where sustainability is paramount, carbon fiber sheets present an intriguing case. While the production of carbon fiber can be energy-intensive, the lightweight nature of the material contributes to fuel savings in industries like aerospace and automotive. Furthermore, advancements in recycling technologies are paving the way for more sustainable use of carbon fiber materials.

The versatility of carbon fiber sheets is reflected in the variety of types available, each tailored to specific applications:

Carbon fiber cloth sheets are crafted from woven carbon fabric, often chosen for their aesthetic appeal and flexibility. These sheets are perfect for applications where visual design is as crucial as functionality, such as in consumer electronics or decorative panels.

Pre-preg sheets come pre-impregnated with resin, ensuring consistent quality and eliminating the need for additional resin application. This makes them ideal for high-performance applications where precision and strength are paramount, such as in aircraft components or high-end automotive parts.

These sheets feature fibers aligned in a single direction, offering maximum strength along that axis. This directional strength makes them suitable for applications like wind turbine blades or certain structural components in construction, where specific load-bearing capacities are required.

A newer addition to the market, hybrid carbon fiber sheets combine carbon fibers with other materials like Kevlar or fiberglass. These sheets provide enhanced properties such as improved impact resistance or cost-efficiency, making them suitable for a range of applications from sports equipment to automotive interiors.

Advantages of Carbon Fiber Sheets

Carbon fiber sheets offer a spectrum of advantages, making them indispensable across various sectors:

Lightweight and Strong

The hallmark of carbon fiber sheets is their exceptional strength-to-weight ratio. With a strength that is five times that of steel and twice as stiff, yet at a fraction of the weight, carbon fiber is indispensable in industries where weight reduction translates to enhanced performance and efficiency, such as in aerospace and competitive automotive sectors.

Corrosion Resistance

Carbon fiber sheets excel in resisting corrosion, making them ideal for use in harsh environments. Unlike metals, they are impervious to rust, which is particularly advantageous in marine applications where exposure to water and salt is constant, or in chemical processing plants where exposure to corrosive substances is frequent.

Thermal Stability

The thermal stability of carbon fiber sheets is another significant advantage. They maintain their structural integrity across a broad temperature range, which is crucial in industries like aerospace, where materials are exposed to extreme temperature fluctuations during flight.

Electrical Conductivity

While not as conductive as metals, carbon fiber sheets offer a level of electrical conductivity that can be beneficial in specific applications. For instance, in industries where electromagnetic interference needs to be minimized, carbon fiber can provide a suitable alternative to traditional conductive materials.

Versatility and Customization

Carbon fiber sheets can be customized to meet specific requirements, offering unmatched versatility. They can be cut, shaped, and molded into complex designs, enabling innovations in architecture, industrial design, and consumer products, where unique shapes and forms are desired.

Applications of Carbon Fiber Sheets

The unique properties of carbon fiber sheets have led to their adoption across a range of industries:

Aerospace Innovations

In the aerospace industry, carbon fiber sheets are used in aircraft structures to reduce weight and improve fuel efficiency. Their strength and durability make them ideal for critical components like fuselage panels and wing assemblies, where performance and safety are paramount.

Automotive Advancements

Carbon fiber sheets are revolutionizing the automotive industry, particularly in high-performance vehicles. They are used in body panels, spoilers, and even interior components to enhance speed, handling, and overall vehicle performance, while also contributing to fuel efficiency through weight reduction.

Sporting Goods Evolution

In the world of sporting goods, carbon fiber has become synonymous with high performance. From bicycles to tennis rackets, the use of carbon fiber enhances strength and reduces weight, allowing athletes to perform at their best. The material's flexibility and resilience also contribute to better shock absorption and durability.

Marine Engineering

The marine industry benefits greatly from carbon fiber sheets due to their resistance to corrosion and lightweight nature. They are used in boat hulls and components, where they provide durability and performance enhancements without adding significant weight, crucial for speed and fuel efficiency.

Where to Buy Carbon Fiber Sheets

If you're considering incorporating carbon fiber sheets into your project, there are several purchasing avenues to explore:

Online Retailers

Online platforms specializing in carbon fiber materials offer a diverse array of products, from carbon fiber cloth and rolls to pre-preg sheets. These websites often provide detailed product information and customer reviews, making it easier to select the right material for your specific needs. Look for reputable sites that offer secure transactions and clear return policies.

Specialty Stores

For those seeking expert advice and a more hands-on experience, specialty stores focusing on composite materials are an excellent choice. These stores often employ knowledgeable staff who can offer guidance based on your application's requirements, ensuring you select the most suitable carbon fiber sheets.

Direct from Manufacturers

Purchasing directly from manufacturers can be a cost-effective solution, especially for larger orders. Manufacturers typically offer a broader selection of products and may provide custom solutions tailored to your unique specifications. This route is particularly advantageous for businesses looking to establish a long-term supply partnership.

Understanding Carbon Fiber Pricing

The cost of carbon fiber sheets varies widely and is influenced by several key factors:

Factors Affecting Pricing

- Type of Carbon Fiber: Pre-preg sheets, due to their pre-impregnation with resin, generally cost more than standard cloth sheets. The added processing and materials contribute to a higher price point.

- Thickness and Size: Naturally, thicker and larger sheets come with a higher cost. It's important to balance the need for material strength and coverage with budget considerations.

- Quality and Brand: As with many materials, the quality and brand reputation can affect pricing. High-quality, branded carbon fiber products often come with a premium price tag but offer assurance in terms of performance and reliability.

How Much Does Carbon Fiber Cost?

The price range for carbon fiber sheets can vary significantly, typically from $25 to $200 per square meter. When selecting carbon fiber materials, it's crucial to align your choice with your project's specific needs and budget constraints. Consider both the immediate costs and the long-term benefits of using high-quality carbon fiber.

Conclusion

Carbon fiber sheets present numerous advantages, from their lightweight yet robust nature to their versatility and resistance to corrosion. As industries continue to innovate and seek materials that enhance performance and efficiency, carbon fiber sheets remain a favored choice. Whether you're involved in aerospace, automotive, or other fields, understanding the benefits and applications of carbon fiber can guide you in making informed decisions for your projects.

When exploring carbon fiber sheets for your next venture, consider the various options available from online retailers, specialty stores, and direct manufacturers. By understanding the types of carbon fiber sheets and their pricing, you can find the right material to meet your needs and budget.

With their impressive properties and expanding range of applications, carbon fiber sheets are more than just a trend; they are a proven solution for modern engineering challenges.