Welcome to Mondince Bike - A well-known factory specialized in produce carbon bike frame and other parts since 2007.

Applications of Carbon Fiber in Industry

Carbon fiber is a remarkable material known for its unique properties and wide-ranging applications. Its strength, light weight, and versatility make it a preferred choice across various industries. In this article, we'll explore the characteristics of carbon fiber and delve into its applications in different sectors. As industries evolve, the demand for materials that offer both durability and efficiency increases, positioning carbon fiber as a material of choice. Understanding its properties and potential applications is crucial for leveraging its benefits in modern industry.

What is Carbon Fiber?

Carbon fiber is a strong, lightweight material made of thin, crystalline filaments of carbon. Each strand of carbon fiber is composed of carbon atoms bonded together in a long chain. This structure gives carbon fiber its impressive strength and rigidity. The production of carbon fiber involves a complex process where organic polymers are carbonized under high heat, resulting in the formation of these fibers. This process not only enhances the strength of the fibers but also imparts a high degree of flexibility, allowing them to be woven into various forms. The versatility of carbon fiber stems from its ability to be molded into complex shapes without losing its inherent strength, making it suitable for a myriad of applications.

Key Characteristics of Carbon Fiber

Carbon fiber is celebrated for several key characteristics:

- High Strength: Carbon fiber has a high tensile strength, meaning it can withstand a lot of tension without breaking. This makes it particularly useful in applications requiring durability. The strength of carbon fiber is often compared to steel, yet it surpasses it in tensile strength while maintaining a fraction of the weight. This property is crucial in industries where both strength and weight play a pivotal role in the performance and efficiency of the final product.

- Lightweight: Despite its strength, carbon fiber is incredibly lightweight, which is why it's often used in industries where reducing weight is critical. The lightweight nature of carbon fiber significantly contributes to energy efficiency, especially in transport industries. By reducing the overall weight of vehicles, manufacturers can achieve better fuel economy and lower emissions, aligning with global sustainability goals.

- Corrosion Resistance: Carbon fiber is resistant to corrosion, making it ideal for use in harsh environments. Unlike metals that may rust or degrade over time, carbon fiber maintains its integrity, offering longevity in applications exposed to moisture and chemicals. This resistance to environmental degradation is particularly beneficial in marine applications, where exposure to saltwater can be detrimental to other materials.

- Thermal Stability: It maintains its properties even at high temperatures, which is essential for applications in aerospace and automotive industries. The ability to withstand extreme temperatures without losing mechanical properties ensures reliability in high-stress environments such as engines and exhaust systems. This thermal stability also means carbon fiber can be used in combination with other materials to enhance their overall performance.

Mechanical Properties of Carbon Fiber

Carbon Fiber Tensile Strength

Tensile strength is one of the most significant properties of carbon fiber. It measures the force required to pull something to the point where it breaks. Carbon fiber's tensile strength is typically much higher than that of steel, making it a strong contender for materials used in construction and manufacturing. This superior tensile strength allows for the creation of lightweight structures that do not compromise on safety or durability. In high-stakes applications, such as aerospace, this property ensures that components can withstand significant stress without failure.

Carbon Fiber Density

The density of carbon fiber is relatively low compared to metals like steel and aluminum. This low density contributes to its lightweight nature, making it an excellent choice for applications where weight reduction is crucial. A lower density material is easier to handle and transport, reducing logistics costs and improving overall efficiency. In addition to transportation benefits, the low density of carbon fiber means that structures can be more easily maneuvered and assembled, offering practical advantages in construction and installation processes.

Elastic Modulus of Carbon Fiber

The elastic modulus, or tensile modulus, of carbon fiber indicates its stiffness. A higher modulus means the material is stiffer and less likely to deform under stress. Carbon fiber's high elastic modulus is one reason it's used in applications requiring precision and stability. This rigidity is crucial in scenarios where dimensional accuracy and minimal deflection are necessary, such as in precision instruments and high-performance sporting equipment. Moreover, the ability to maintain shape under load makes carbon fiber a preferred material in the creation of stable and reliable structural components.

Applications in Various Industries

Automotive Industry

The automotive industry has embraced carbon fiber for its ability to enhance vehicle performance. By replacing heavier materials with carbon fiber, manufacturers can improve fuel efficiency and increase speed. Carbon fiber is used in car body panels, hoods, and even entire car frames in some high-performance vehicles. The reduction in weight not only improves acceleration and handling but also contributes to reduced emissions, supporting environmental initiatives. As electric vehicles gain popularity, carbon fiber plays a vital role in offsetting the weight of heavy batteries, ensuring these vehicles remain efficient and agile.

Aerospace Industry

In the aerospace sector, carbon fiber is valued for its strength-to-weight ratio. Aircraft designers use carbon fiber composites to reduce weight while maintaining structural integrity. This results in more fuel-efficient aircraft with longer range capabilities. The use of carbon fiber in aerospace extends beyond commercial aviation; it is also integral in the development of spacecraft, where weight is a critical factor in the success of missions. Furthermore, the durability of carbon fiber ensures that aircraft can withstand the rigors of flight, from takeoff to landing, without compromising passenger safety.

Sports Equipment

Carbon fiber is a popular choice in sports equipment manufacturing. From bicycles and tennis rackets to fishing rods and golf clubs, the lightweight and strong nature of carbon fiber enhances performance and user experience. Athletes benefit from the reduced weight and increased control these materials offer. The vibration damping properties of carbon fiber also contribute to improved comfort and precision, allowing athletes to perform at their best. Additionally, the aesthetic appeal of carbon fiber, with its sleek and modern appearance, adds to its desirability in high-end sporting goods.

Construction and Infrastructure

In construction, carbon fiber is used to reinforce concrete structures. Its high strength and resistance to environmental factors make it an ideal material for strengthening bridges, buildings, and other infrastructure. Carbon fiber-reinforced materials extend the lifespan of these structures while reducing maintenance costs. The ability to retrofit existing structures with carbon fiber composites offers a cost-effective solution to enhance their load-bearing capacity. As urban areas expand and infrastructure demands grow, carbon fiber provides a sustainable option for building resilient and lasting structures.

The Chemistry Behind Carbon Fiber

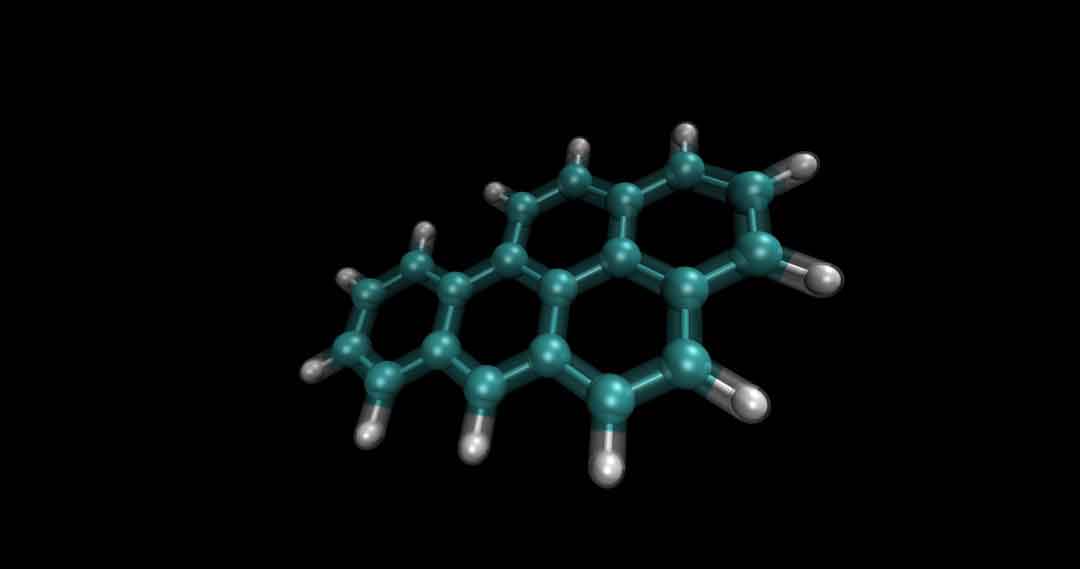

Carbon Fiber Chemical Structure

by Giovanni Crisalfi (https://unsplash.com/@gicrisf)

The chemical structure of carbon fiber consists of long chains of carbon atoms. These atoms are bonded together in a pattern that gives the fibers their strength and resilience. The tightly packed structure of carbon atoms in carbon fiber is what allows it to have such a high strength-to-weight ratio. This microscopic arrangement is the result of careful engineering during the manufacturing process, where precise control over temperature and tension ensures optimal fiber properties. Understanding the chemical composition of carbon fiber helps in tailoring its characteristics for specific applications, maximizing performance.

Is Carbon Fiber a Metal?

Despite its metallic appearance, carbon fiber is not a metal. It is a composite material made from organic polymers that are carbonized to form the fibers. This process involves heating the material to high temperatures, which removes non-carbon atoms and leaves behind a strong carbon structure. The resulting fibers are then combined with resins to create composite materials that offer superior strength and versatility. This distinction from metals is important as it highlights the unique qualities of carbon fiber, which include non-magnetic properties and resistance to electrical conductivity, making it suitable for specialized applications.

Advancements in Carbon Fiber Technology

Innovations in Carbon Fiber Manufacturing

Recent advancements in carbon fiber manufacturing have led to even stronger and lighter materials. New techniques have improved the efficiency of production processes, reducing costs and expanding the use of carbon fiber in various industries. Innovations such as 3D printing with carbon fiber composites are opening new avenues for customization and rapid prototyping. As manufacturing technologies evolve, the potential to create more complex and tailored carbon fiber components grows, offering businesses competitive advantages in product development.

Future Prospects

The future of carbon fiber looks promising, with ongoing research focused on enhancing its properties and finding new applications. As technology advances, we can expect to see carbon fiber integrated into more products, further revolutionizing industries. Emerging fields such as renewable energy are exploring the use of carbon fiber in wind turbine blades and solar panel frames, where its lightweight and durable nature can significantly improve efficiency. The continuous development of carbon fiber technologies promises to drive innovation and sustainability across multiple sectors, shaping the next generation of industrial applications.

Conclusion

Carbon fiber's unique combination of strength, light weight, and versatility makes it an invaluable material in modern industry. From automotive and aerospace applications to sports equipment and construction, its benefits are clear. As we continue to innovate and explore new possibilities, carbon fiber will undoubtedly play a significant role in shaping the future of technology and design. Its potential to contribute to sustainable development and technological advancement presents exciting opportunities for industries worldwide. As research progresses and new applications emerge, carbon fiber will remain at the forefront of material science, offering solutions that meet the ever-evolving demands of the global market.