Welcome to Mondince Bike - A well-known factory specialized in produce carbon bike frame and other parts since 2007.

Benefits of Carbon Fiber in Manufacturing

Carbon fiber is revolutionizing the manufacturing world. This advanced material is known for its incredible strength, lightweight nature, and versatility. As industries continuously seek ways to innovate, carbon fiber stands out as a beacon of modern engineering. Its unique properties allow manufacturers to push the boundaries of design and performance, enabling the creation of products that were once thought impossible. In this article, we'll explore the benefits of carbon fiber in manufacturing and why it is becoming a crucial component across various sectors.

by Frames For Your Heart (https://unsplash.com/@framesforyourheart)

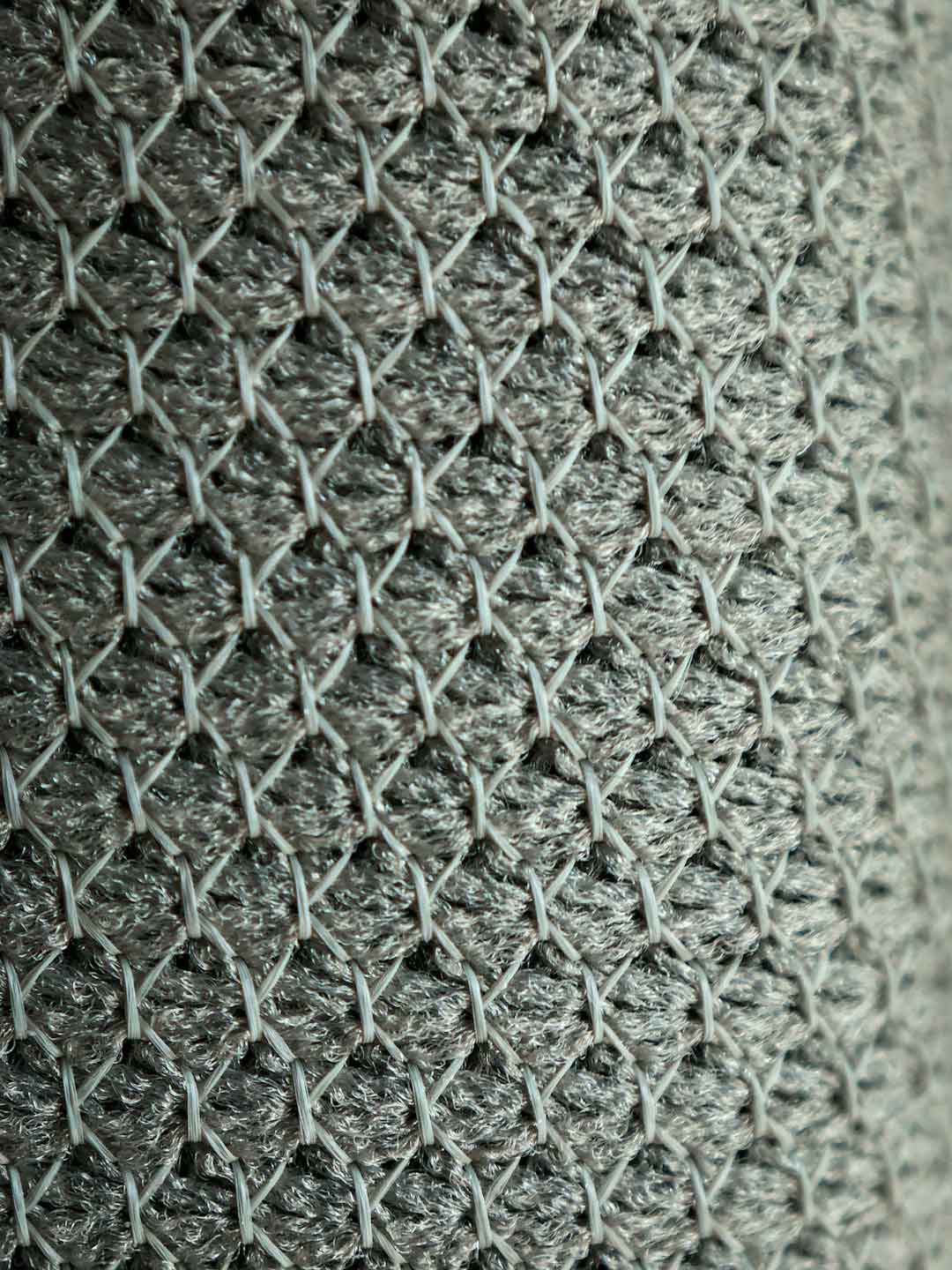

Carbon fiber is a material composed of thin, strong crystalline filaments of carbon. It's incredibly durable yet lightweight, making it an ideal choice for many applications. When these fibers are woven together and combined with a resin, they form a composite that can be molded into various shapes. This adaptability is one reason carbon fiber is popular in industries ranging from aerospace to sports equipment. The ability to tailor the fiber's orientation and layer thickness allows engineers to optimize the material for specific applications, enhancing performance and reducing waste.

The production process of carbon fiber involves a complex series of steps, starting with the precursor material, typically polyacrylonitrile (PAN). The precursor undergoes stabilization, carbonization, and surface treatment, resulting in the formation of carbon fiber filaments. This intricate process contributes to the material's high cost, but ongoing research and technological advancements are aimed at reducing production expenses, making carbon fiber more accessible to a broader range of industries.

Key Advantages of Carbon Fiber

Strength and Durability

One of the most significant advantages of carbon fiber is its strength. Carbon fiber is five times stronger than steel and twice as stiff, yet it weighs much less. This strength-to-weight ratio is unmatched by traditional materials, making it ideal for applications where durability is crucial. The high tensile strength of carbon fiber allows it to withstand substantial loads and stresses, making it a preferred material for critical structural components.

Furthermore, carbon fiber's durability extends to its fatigue resistance. Unlike metals, which can suffer from fatigue failure over time, carbon fiber maintains its structural integrity even after repeated stress cycles. This property is particularly valuable in industries such as aerospace and automotive, where safety and reliability are paramount. The combination of strength and durability ensures that carbon fiber components can endure harsh conditions and extend the lifespan of products.

Lightweight Properties

The lightweight nature of carbon fiber is one of its standout features. For industries like automotive and aerospace, reducing weight can lead to significant improvements in fuel efficiency and performance. For instance, using carbon fiber in vehicle manufacturing can reduce the car's weight without compromising safety or performance, leading to better fuel economy and lower emissions. The reduction in weight also contributes to enhanced handling and acceleration, offering a superior driving experience.

In addition to its benefits in transportation, the lightweight properties of carbon fiber are advantageous in applications such as sporting goods and medical devices. Athletes benefit from equipment that is easier to maneuver, while medical professionals appreciate the precision and ease of handling provided by lighter tools and prosthetics. The ability to reduce weight without sacrificing strength or performance is a key factor driving the widespread adoption of carbon fiber across diverse sectors.

Resistance to Corrosion and Chemicals

Carbon fiber is highly resistant to corrosion and most chemicals. Unlike metals, it doesn't rust or corrode, which means products made from carbon fiber have a longer lifespan and require less maintenance. This property is particularly beneficial in industries like marine and construction, where materials are often exposed to harsh environments. The resistance to corrosion ensures that structures and components remain intact and functional, even in challenging conditions.

In addition to its corrosion resistance, carbon fiber's chemical stability makes it suitable for use in environments where exposure to aggressive substances is common. This includes applications in the chemical processing industry, where equipment must withstand contact with various chemicals without degrading. The longevity and reliability of carbon fiber components contribute to cost savings and improved safety in demanding settings.

Thermal and Electrical Conductivity

While not as conductive as metals, carbon fiber exhibits excellent thermal and electrical conductivity. This makes it useful in applications requiring heat dissipation or electrical conduction, such as in electronics or energy sectors. Carbon fiber's ability to conduct heat efficiently helps prevent overheating and enhances the performance of electronic devices.

Moreover, its electrical conductivity opens up possibilities for innovative applications in fields like telecommunications and renewable energy. Carbon fiber can be used in the manufacture of antennas, batteries, and other components where efficient energy transfer is essential. The versatility of carbon fiber in conducting heat and electricity expands its potential uses and underscores its value as a multifunctional material.

Applications of Carbon Fiber

Aerospace and Defense

The aerospace industry was one of the first to adopt carbon fiber, taking advantage of its lightweight and strong properties. Aircraft components made from carbon fiber contribute to fuel efficiency, increased payload capacity, and reduced maintenance costs. The reduction in weight allows for longer flight ranges and greater fuel savings, making carbon fiber an invaluable material in modern aircraft design.

Carbon fiber's application in defense extends beyond aircraft to include unmanned aerial vehicles (UAVs), missiles, and protective gear. Its strength and durability enhance the performance and reliability of military equipment, while its lightweight nature ensures rapid deployment and agility. As defense strategies evolve, the demand for advanced materials like carbon fiber continues to grow, driving innovation in the sector.

Automotive Industry

by Rob Wingate (https://unsplash.com/@robwingate)

In the automotive industry, carbon fiber is used to manufacture lightweight, high-performance parts. From body panels to interior components, car manufacturers are increasingly using carbon fiber to enhance vehicle performance and efficiency. Luxury and sports cars, in particular, benefit from carbon fiber's lightweight and aesthetic appeal. The sleek, modern look of carbon fiber complements the design of high-end vehicles, appealing to consumers seeking both performance and style.

Beyond luxury vehicles, mainstream automakers are exploring the use of carbon fiber to meet stringent fuel efficiency and emissions standards. The incorporation of carbon fiber into electric vehicles, for example, can extend battery life and increase driving range. As the automotive industry shifts towards sustainable transportation solutions, carbon fiber's role in reducing environmental impact becomes increasingly important.

Sporting Goods

Carbon fiber's strength and lightweight nature make it a popular choice in the sporting goods industry. From bicycles and tennis rackets to golf clubs and hockey sticks, carbon fiber enhances performance by reducing weight while maintaining durability. Athletes gain a competitive edge with equipment that is lighter, faster, and more responsive, contributing to improved performance and reduced fatigue.

The versatility of carbon fiber also allows for the customization of sporting equipment to suit individual preferences and needs. Manufacturers can adjust the stiffness and flexibility of carbon fiber components, providing athletes with tailored solutions for optimal performance. As new sports and recreational activities emerge, the demand for advanced materials like carbon fiber is expected to rise, driving innovation in the industry.

Wind Energy

In the renewable energy sector, carbon fiber is used to manufacture wind turbine blades. The material's lightweight and strong properties allow for longer blades, which can capture more wind and generate more energy, contributing to sustainable manufacturing solutions. The increased efficiency of wind turbines with carbon fiber blades supports the transition to clean energy sources and reduces reliance on fossil fuels.

Furthermore, carbon fiber's durability and resistance to environmental factors ensure the longevity and reliability of wind turbines. As the global demand for renewable energy grows, the use of carbon fiber in wind energy applications is likely to expand, playing a crucial role in the development of sustainable energy infrastructure.

Medical Equipment

In the medical field, carbon fiber is used to create advanced medical imaging equipment and prosthetics. Its biocompatibility and strength make it ideal for applications where precision and reliability are crucial. Carbon fiber prosthetics offer patients greater mobility and comfort, enhancing their quality of life and supporting rehabilitation efforts.

The use of carbon fiber in medical imaging equipment, such as MRI and CT scanners, improves image clarity and reduces interference, leading to more accurate diagnoses. As healthcare technology advances, the demand for materials that enhance performance and patient outcomes continues to drive innovation in medical applications of carbon fiber.

Sustainable Manufacturing with Carbon Fiber

As industries strive for sustainability, carbon fiber offers several environmental benefits. Its lightweight nature reduces energy consumption in transportation applications, contributing to lower emissions. Moreover, carbon fiber composites can be recycled, although the process is currently more complex than traditional materials. Advances in recycling technology are improving, promising even more sustainable manufacturing innovations in the future.

Efforts to develop more efficient recycling methods for carbon fiber are underway, with researchers exploring new techniques to recover and repurpose carbon fiber from end-of-life products. These advancements are expected to reduce waste and lower the environmental impact of carbon fiber manufacturing. As the demand for sustainable solutions grows, the role of carbon fiber in promoting eco-friendly practices is likely to expand, influencing a wide range of industries.

Challenges and Considerations

While carbon fiber offers numerous advantages, there are challenges to consider. The production of carbon fiber can be expensive, which may limit its use in some applications. Additionally, the recycling process for carbon fiber composites is still developing, posing challenges for end-of-life product management. The high cost of production is primarily due to the energy-intensive processes involved and the need for specialized equipment and expertise.

Despite these challenges, the advantages of carbon fiber often outweigh the drawbacks, particularly in applications where performance is paramount. Industries are continually seeking ways to reduce production costs and improve recycling techniques, making carbon fiber more accessible and sustainable. As technology advances and economies of scale are achieved, the cost barriers associated with carbon fiber are expected to decrease, paving the way for broader adoption across various sectors.

Conclusion

Carbon fiber is redefining what's possible in manufacturing. Its exceptional strength, lightweight properties, and versatility make it a valuable material across various industries. As technology advances and the demand for sustainable solutions grows, carbon fiber will play an increasingly important role in manufacturing innovations. The material's unique properties offer opportunities for creating products that are stronger, lighter, and more efficient than ever before.

Whether it's enhancing the performance of vehicles, improving energy efficiency, or creating cutting-edge sporting goods, the benefits of carbon fiber are clear. As we continue to push the boundaries of what's possible, carbon fiber will undoubtedly remain at the forefront of advanced manufacturing materials. By understanding and leveraging the advantages of carbon fiber, industries can achieve greater efficiency, performance, and sustainability—ushering in a new era of manufacturing excellence. The future of manufacturing is bright, and carbon fiber is poised to be a key driver of innovation and progress.