Welcome to Mondince Bike - A well-known factory specialized in produce carbon bike frame and other parts since 2007.

The Future of Carbon Fiber Technology

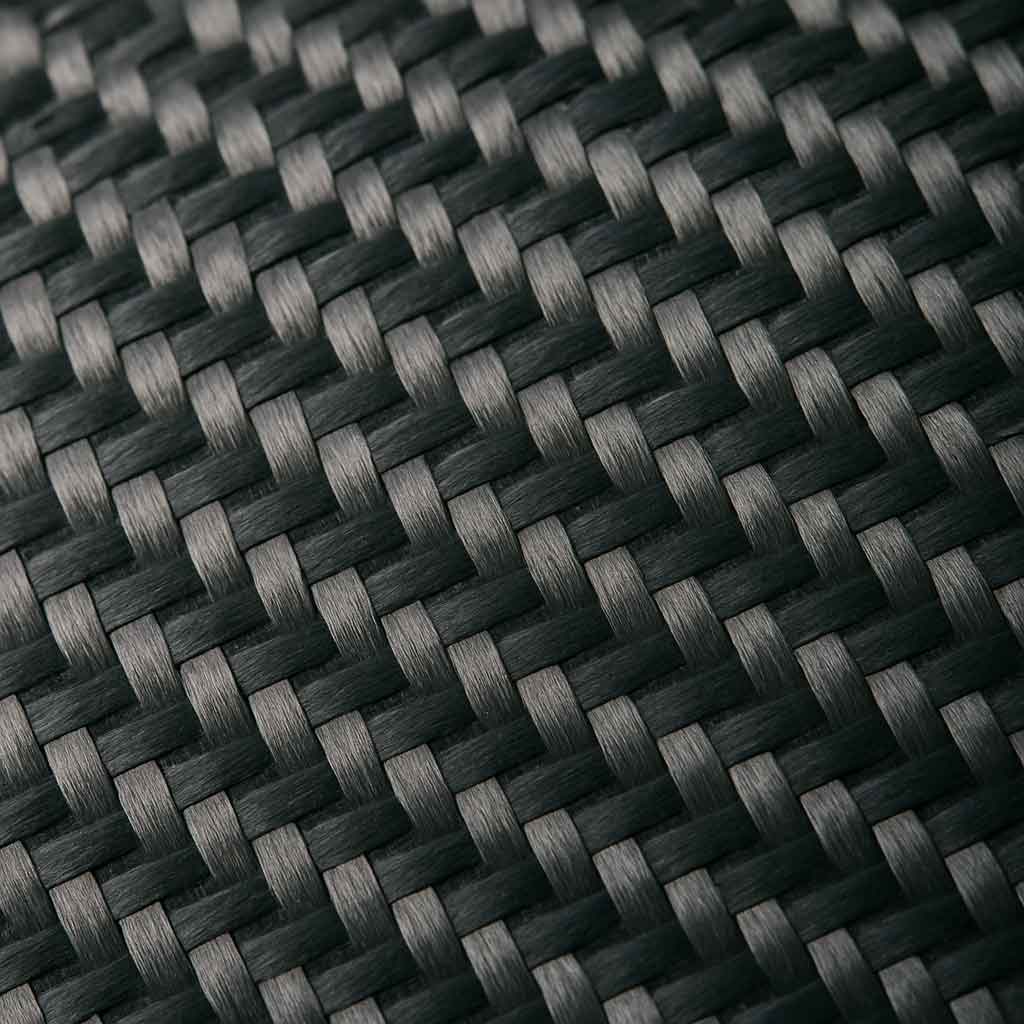

Composition and Structure

At its core, carbon fiber is composed of thin, robust crystalline filaments of carbon. These filaments are tightly woven to create a fabric-like structure that serves as the foundation for a composite material when combined with a suitable resin. The resulting composite boasts exceptional strength while maintaining a lightweight profile, qualities that make it highly sought after in various applications.

The unique structure of carbon fiber allows it to distribute loads evenly across its surface. This characteristic is particularly beneficial in applications requiring high performance under stress, making carbon fiber a material of choice in sectors such as aerospace and automotive engineering.

Manufacturing Processes

Carbon fiber production involves several intricate steps, beginning with the precursor material, typically polyacrylonitrile (PAN). This precursor undergoes stabilization, carbonization, and surface treatment processes to transform it into carbon fiber. Each stage is crucial in determining the fiber's final properties, such as its tensile strength and elasticity.

Advancements in manufacturing techniques, including automated layup methods and the integration of 3D printing technologies, are revolutionizing the production of carbon fiber. These innovations not only enhance precision and complexity in design but also make carbon fiber more accessible and cost-effective for widespread use.

Properties and Advantages

Carbon fiber's unique properties set it apart from traditional materials. Its strength-to-weight ratio is unmatched, with carbon fiber being five times stronger than steel while remaining two-thirds lighter. Additionally, it exhibits remarkable resistance to corrosion and chemical damage, prolonging the lifespan of components made from it.

Thermal stability is another key advantage, allowing carbon fiber to perform exceptionally well in extreme temperatures. This quality is particularly valuable in industries such as aerospace, where materials are subjected to harsh environmental conditions.

Current Applications of Carbon Fiber

Automotive Industry

Enhancing Vehicle Performance

The automotive industry is one of the most significant adopters of carbon fiber technology. High-performance vehicles leverage carbon fiber to enhance speed and efficiency by reducing overall vehicle weight. This reduction in weight translates to improved fuel economy and lower emissions, aligning with global efforts to create more sustainable transportation solutions.

Components and Integration

Car manufacturers are increasingly incorporating carbon fiber into various vehicle components, including body panels, interiors, and even entire frames. The use of carbon fiber not only enhances the aesthetic appeal of vehicles but also contributes to safety by maintaining structural integrity during high-impact events.

Future Trends in Automotive

Looking ahead, the integration of carbon fiber in electric and autonomous vehicles holds great promise. By reducing the weight of these vehicles, carbon fiber can extend battery life and improve overall performance, paving the way for more efficient and environmentally friendly transportation solutions.

Aerospace Sector

Structural Advancements

In the aerospace sector, the lightweight and robust nature of carbon fiber is indispensable. Aircraft manufacturers incorporate carbon fiber into critical components such as wings, fuselages, and tail assemblies to reduce weight and enhance fuel efficiency. This reduction in weight also allows for increased payload capacity, offering airlines economic advantages.

Enhancing Safety and Performance

Carbon fiber's strength contributes significantly to the structural integrity of aircraft, enhancing safety during flight. Its resistance to fatigue and corrosion ensures that aircraft components can withstand the rigors of frequent use and harsh environmental conditions, reducing maintenance costs and downtime.

Innovations in Aerospace Design

The future of aerospace design is set to be revolutionized by carbon fiber technology. As manufacturers explore new composite materials and advanced production techniques, the potential for lighter, more efficient aircraft becomes increasingly attainable. These advancements could lead to faster, more economical flights and new possibilities in space exploration.

Sports Equipment

Performance Enhancement

Carbon fiber's lightweight and strong characteristics make it an ideal material for sports equipment, enhancing athletic performance. From tennis rackets to bicycles, carbon fiber's ability to improve speed, control, and precision offers athletes a competitive edge.

Durability and Flexibility

Sports equipment made from carbon fiber is not only lightweight but also highly durable, resisting wear and tear over time. Its flexibility allows for the creation of innovative designs that can adapt to the specific needs of different sports, providing customized solutions for athletes.

Expansion into New Sports

As carbon fiber technology continues to evolve, its application in sports is expanding beyond traditional equipment. Emerging sports and activities are increasingly embracing carbon fiber for its performance-enhancing qualities, leading to innovations in equipment design and functionality.

Renewable Energy

Wind Turbine Advancements

In the realm of renewable energy, carbon fiber plays a critical role in the development of efficient wind turbine blades. These blades, constructed from carbon fiber composites, are lighter and more efficient, enabling greater energy capture and reducing manufacturing costs. This makes carbon fiber an essential material in the pursuit of sustainable energy solutions.

Solar Energy Innovations

Beyond wind energy, carbon fiber is being explored for use in solar energy applications. Its lightweight and durable nature make it a promising candidate for solar panel frames and support structures, potentially increasing the efficiency and longevity of solar power systems.

Future of Renewable Energy

As the demand for clean energy continues to rise, carbon fiber's role in the renewable energy sector is expected to grow. Innovations in material science and production techniques are likely to yield even more efficient and cost-effective solutions, accelerating the transition to a sustainable energy future.

Recent Advancements in Carbon Fiber Technology

Sustainable Carbon Fiber

Eco-Friendly Production Methods

With growing environmental concerns, the focus has shifted towards sustainable carbon fiber production. Researchers are pioneering eco-friendly manufacturing processes that aim to reduce energy consumption and minimize waste. Innovations such as bio-based resins and recycling methods are paving the way for a more sustainable carbon fiber industry.

Recycling and Reuse

The development of effective recycling methods for carbon fiber is a significant step towards sustainability. By reclaiming and reprocessing used carbon fiber, manufacturers can reduce environmental impact and lower production costs, making carbon fiber more accessible and environmentally friendly.

Impact on Industry Practices

The push for sustainability is transforming industry practices, encouraging companies to adopt greener production methods. As these practices become more widespread, the carbon fiber industry is poised to become a model for sustainable manufacturing, contributing to global efforts to reduce environmental impact.

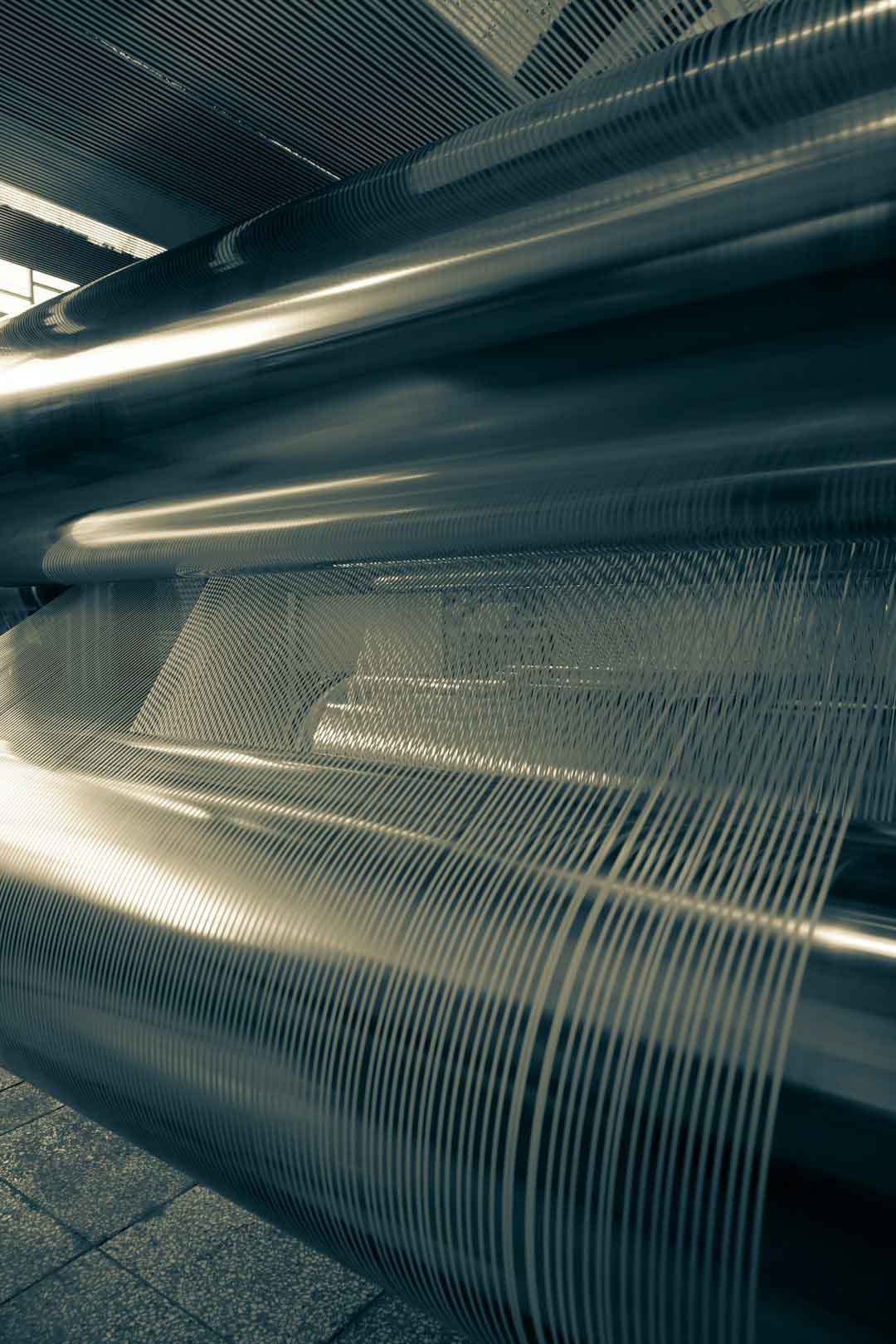

Enhanced Manufacturing Techniques

by Morteza Mohammadi (https://unsplash.com/@morophoto)

Automated Production Processes

Advancements in manufacturing, such as automated layup techniques, are revolutionizing the carbon fiber industry. These automated processes increase efficiency and precision, allowing for the production of more complex and intricate designs. As a result, carbon fiber is becoming more accessible and affordable for a wide range of applications.

3D Printing Innovations

The integration of 3D printing technology into carbon fiber production is opening new avenues for innovation. This technology enables the creation of customized components with complex geometries, expanding the potential applications of carbon fiber in industries ranging from aerospace to consumer goods.

Cost Reduction Strategies

As manufacturing techniques improve, the cost of carbon fiber production continues to decrease. This reduction in cost is making carbon fiber more competitive with traditional materials, encouraging its adoption across various industries and contributing to the growth of the carbon fiber market.

Improved Performance

Advancements in Composite Materials

Ongoing research is leading to the development of carbon fiber composites with enhanced properties. Innovations in fiber coatings and matrix materials are resulting in even stronger, more durable composites, capable of withstanding extreme conditions and offering improved performance.

Tailored Material Properties

By manipulating the composition and structure of carbon fiber composites, researchers are able to tailor material properties to specific applications. This customization allows for the creation of materials that meet the unique demands of different industries, enhancing the versatility of carbon fiber technology.

Future Research Directions

The future of carbon fiber research holds promise for further advancements in material performance. As scientists explore new fiber and matrix combinations, the potential for even more robust and versatile carbon fiber composites becomes increasingly attainable, paving the way for innovative applications across diverse sectors.

Future Potential of Carbon Fiber

Urban Transportation

Revolutionizing Public Transit

The future of carbon fiber technology holds immense promise for urban transportation systems. By utilizing lightweight carbon fiber composites, public transit vehicles such as buses and trains can achieve greater energy efficiency and reduced emissions, contributing to more sustainable urban environments.

Electric and Autonomous Vehicles

As the automotive industry shifts towards electric and autonomous vehicles, carbon fiber's role becomes even more critical. The material's lightweight properties can extend the range of electric vehicles and improve the performance of autonomous systems, paving the way for more advanced and sustainable transportation solutions.

Infrastructure Integration

Carbon fiber's integration into urban infrastructure extends beyond vehicles. Its use in construction materials, such as bridges and tunnels, can enhance durability and reduce maintenance requirements, leading to more resilient urban environments.

Infrastructure Development

Construction and Architecture

Carbon fiber's durability and resistance to corrosion make it an excellent candidate for infrastructure projects. Buildings and bridges constructed with carbon fiber composites can withstand harsh environmental conditions, reducing the need for frequent repairs and maintenance.

Roadway Innovations

Incorporating carbon fiber into roadway construction offers numerous benefits, including increased longevity and reduced maintenance costs. Its lightweight nature also allows for faster construction times, minimizing disruptions to traffic and enhancing overall infrastructure efficiency.

Environmental Impact

By reducing the environmental impact of construction projects, carbon fiber plays a crucial role in sustainable infrastructure development. Its use in eco-friendly building materials aligns with global efforts to create more sustainable cities and communities.

Medical Devices

Prosthetics and Implants

In the medical field, carbon fiber's biocompatibility and strength offer new possibilities for prosthetics and implants. Lighter, stronger medical devices can improve patient outcomes and quality of life, providing enhanced mobility and comfort for users.

Diagnostic Equipment

Carbon fiber's lightweight and durable properties make it an ideal material for diagnostic equipment, such as imaging devices and surgical tools. Its use in medical technology can enhance precision and reliability, leading to improved diagnostic capabilities and patient care.

Future Medical Innovations

As research into carbon fiber's medical applications continues, the potential for new innovations in healthcare becomes increasingly apparent. The development of advanced medical devices and technologies utilizing carbon fiber could revolutionize patient care and treatment outcomes.

Space Exploration

Spacecraft Design

As the space industry expands, carbon fiber will play a crucial role in spacecraft design. Its lightweight and strength are vital for overcoming the challenges of space travel, enabling more ambitious missions and exploration. By reducing the weight of spacecraft components, carbon fiber can improve fuel efficiency and payload capacity, opening new possibilities for space exploration.

Satellite Applications

The use of carbon fiber in satellite construction offers numerous advantages, including increased durability and resistance to the harsh conditions of space. These benefits can extend the lifespan of satellites and improve their performance, contributing to more reliable and efficient space operations.

Future Exploration Missions

Carbon fiber's role in future space exploration missions is expected to grow as the industry continues to innovate. Its potential to enhance the performance and efficiency of spacecraft will be critical in achieving the ambitious goals of future space missions, from lunar exploration to interplanetary travel.

Challenges in Carbon Fiber Technology

While carbon fiber offers many advantages, challenges remain in its widespread adoption. The high cost of production and limited recycling options are significant hurdles that need to be addressed. However, ongoing research and technological advancements are making strides in overcoming these obstacles, making carbon fiber more accessible and sustainable.

Efforts to reduce production costs and develop effective recycling methods are essential for the future growth of the carbon fiber industry. By addressing these challenges, carbon fiber can become a more viable option for a broader range of applications, contributing to its continued success and impact across various industries.

Conclusion

Carbon fiber technology is poised to shape the future of multiple industries, from transportation to renewable energy. As advancements continue, the potential applications of carbon fiber will only expand, offering innovative solutions to contemporary challenges. By embracing sustainable practices and leveraging technological breakthroughs, carbon fiber will remain a cornerstone of advanced materials technology for years to come.

The future is bright for carbon fiber, and its impact will undoubtedly be felt across the globe as industries adopt and innovate with this remarkable material. As research and development efforts progress, carbon fiber will continue to unlock new possibilities, driving progress and transformation in a wide range of fields.