Welcome to Mondince Bike - A well-known factory specialized in produce carbon bike frame and other parts since 2007.

Carbon Fiber vs. Traditional Materials: A Comparison

In the world of materials, carbon fiber has emerged as a revolutionary option, promising high performance across various applications. Its unique properties and potential to transform industries make it a focal point of interest for engineers and designers alike. But how does it stack up against traditional materials like steel, aluminum, and wood? In this article, we'll dive into the advantages and disadvantages of carbon fiber, comparing it to conventional materials to help you understand why it's becoming a popular choice across industries.

Carbon fiber is a lightweight, high-strength material composed of thin, strong crystalline filaments of carbon. These fibers are woven together to create a fabric, which is then molded and set with resin to form a rigid structure. The process involves careful layering and curing to achieve optimal strength and durability. But what sets carbon fiber apart from more traditional materials?

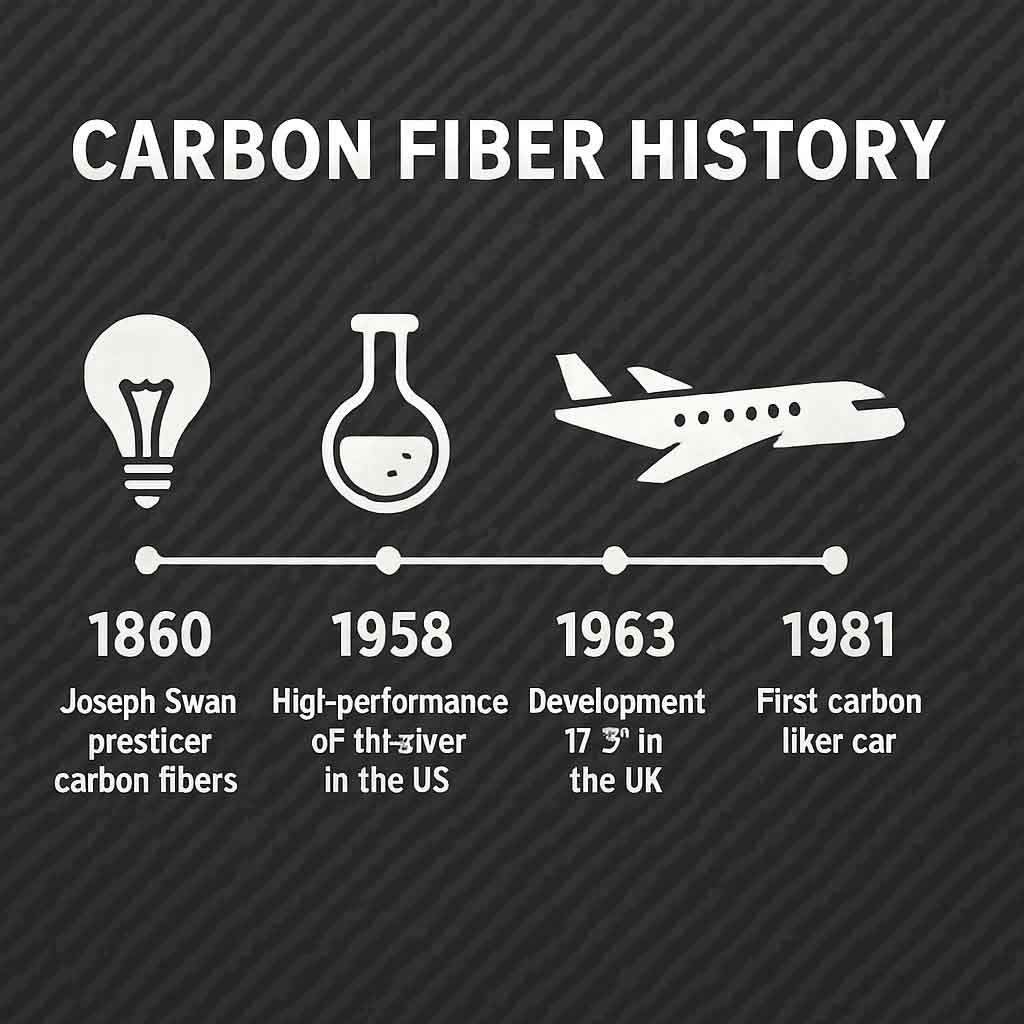

The use of carbon fiber dates back to the 1960s, initially developed for aerospace and military applications due to its high strength-to-weight ratio. Over the years, advancements in manufacturing have made it more accessible, allowing its use to spread into various industries, including automotive, sports equipment, and even consumer electronics. By the 1980s, carbon fiber had made its way into the mainstream, finding applications in everyday products and high-tech innovations alike.

Today, carbon fiber is considered a cutting-edge material that symbolizes technological advancement and innovation. Its evolution from a niche aerospace material to a versatile industrial staple highlights the continuous improvement in production techniques and the growing demand for lightweight, strong, and durable materials. The history of carbon fiber is a testament to human ingenuity and the relentless pursuit of better performance across various fields.

Comparing Carbon Fiber to Traditional Materials

Strength and Durability

One of the most significant advantages of carbon fiber is its unparalleled strength. It's five times stronger than steel and twice as stiff, yet it weighs significantly less. This combination of strength and lightness makes it ideal for applications where weight reduction is crucial without compromising strength, such as in the aerospace and automotive industries. The inherent stiffness of carbon fiber also contributes to the structural integrity of the products, allowing for more innovative designs that are not possible with traditional materials.

Moreover, carbon fiber's durability extends to its resilience against environmental stressors. Unlike metals that may warp or degrade under extreme conditions, carbon fiber maintains its structural integrity over time. This characteristic makes it an appealing choice for applications exposed to harsh environments, where consistent performance is critical. Its ability to withstand significant stress without deformation is a key factor in its growing popularity across various sectors.

Carbon Fiber vs. Steel

Steel is traditionally known for its durability and strength. However, it is also heavy, which can be a disadvantage in applications where weight is a critical factor. Carbon fiber offers a similar level of strength but at a fraction of the weight, making it a preferred choice for performance-driven industries. The weight savings from using carbon fiber can translate to improved speed, efficiency, and overall performance, particularly in industries where every gram counts.

Additionally, carbon fiber's aesthetic appeal cannot be overlooked. Its sleek and modern appearance is often favored in design-centric industries, providing both functional and visual benefits. While steel is robust and versatile, carbon fiber offers a futuristic alternative that aligns with the demands of modern engineering and design. As industries continue to seek materials that offer both performance and visual appeal, carbon fiber stands out as a compelling option.

Weight and Efficiency

The lightweight nature of carbon fiber translates to improved efficiency in various applications. For example, in the automotive industry, reducing the weight of a vehicle can lead to better fuel efficiency and improved performance. Similarly, in aerospace, lighter components can contribute to lower fuel consumption and greater payload capacity. The efficiency gains from using carbon fiber are significant, providing both economic and environmental benefits.

Furthermore, the energy efficiency achieved by using carbon fiber extends beyond operational savings. The reduced weight means less wear and tear on mechanical components, leading to lower maintenance costs and longer product lifespans. This aspect makes carbon fiber not only a smart choice for new designs but also an investment in sustainability and long-term operational savings. The dual benefits of efficiency and longevity make carbon fiber a strategic material choice for forward-thinking industries.

Resistance to Corrosion

Unlike steel, carbon fiber does not rust. This resistance to corrosion makes it an attractive option for use in environments where moisture and chemicals are a concern. This quality also translates to a longer lifespan for products made from carbon fiber, reducing maintenance costs over time. Products that incorporate carbon fiber can remain in service for extended periods without degradation, offering reliability and peace of mind to users.

In addition to its corrosion resistance, carbon fiber's inert nature means it does not react with most chemicals, making it suitable for a wide range of industrial applications. This property is particularly valuable in sectors such as marine and chemical processing, where exposure to corrosive substances is common. The ability of carbon fiber to resist environmental and chemical challenges enhances its value proposition as a durable and long-lasting material.

Cost Considerations

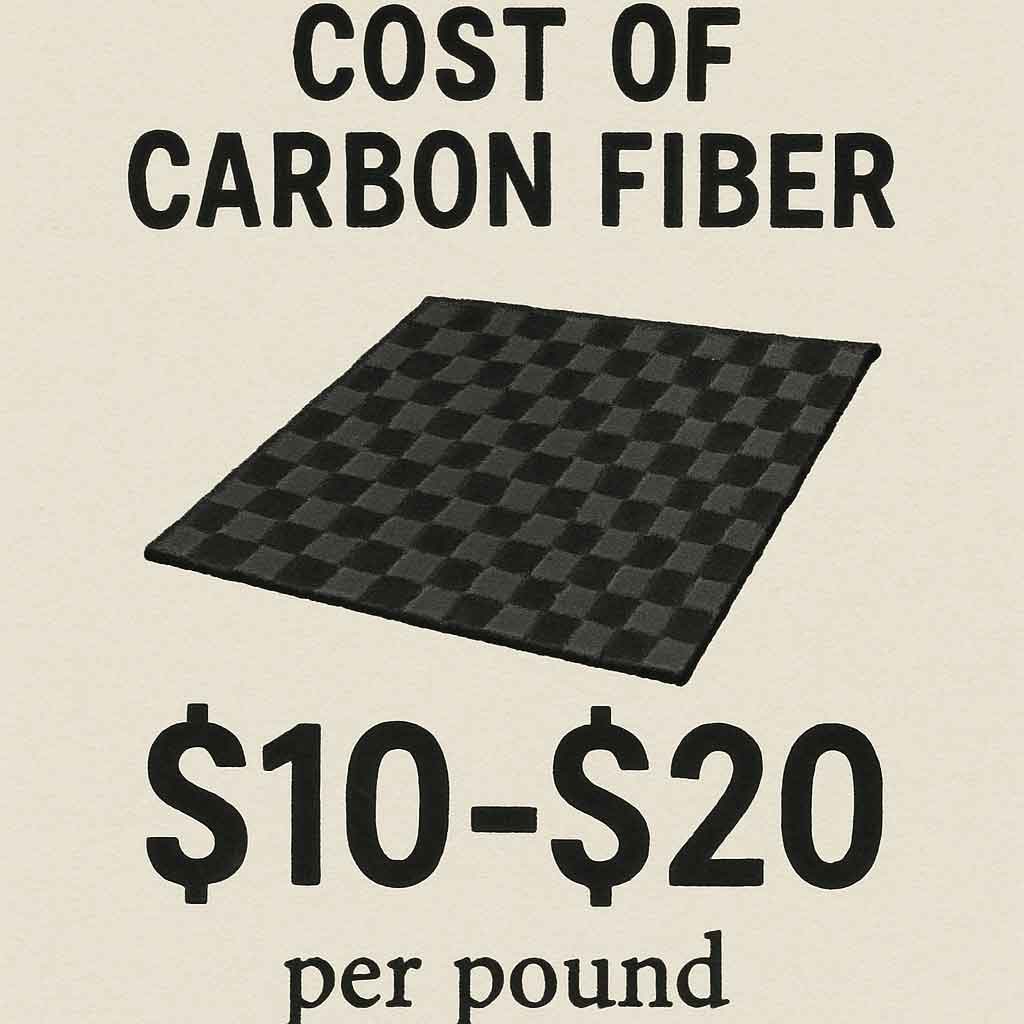

While carbon fiber boasts several advantages, one of its downsides is the cost. Manufacturing carbon fiber is an expensive process, which results in a higher price point compared to traditional materials like steel and aluminum. However, the benefits of weight reduction, improved performance, and durability often justify the initial investment, especially in high-performance applications. Companies must weigh the upfront costs against the long-term savings and performance gains that carbon fiber can provide.

To address cost concerns, ongoing research is focused on developing more cost-effective production methods and sourcing alternative raw materials. These efforts aim to make carbon fiber more accessible to a broader range of industries and applications. As the technology and production techniques continue to evolve, the cost barrier is expected to diminish, paving the way for even wider adoption of carbon fiber across various sectors.

Environmental Impact

The environmental impact of carbon fiber is a topic of ongoing research. While its lightweight nature can lead to reduced emissions in applications like transportation, the production process is energy-intensive. Recycling carbon fiber presents challenges, but advancements are being made to improve its sustainability. Efforts to develop eco-friendly production methods and recycling technologies are crucial in mitigating the environmental footprint of carbon fiber.

In the context of sustainability, carbon fiber offers both challenges and opportunities. While the initial environmental cost is high, the potential for long-term environmental savings through reduced emissions and extended product lifespans is significant. As industries prioritize sustainability, the development of greener carbon fiber technologies will be essential. The pursuit of a sustainable future for carbon fiber reflects broader trends in industrial innovation, where environmental considerations are increasingly driving material choices.

Applications of Carbon Fiber

Carbon fiber is used across a wide range of industries, each benefiting from its unique properties. Here are some key applications:

Automotive Industry

In the automotive sector, carbon fiber is used for high-performance parts such as body panels, wheels, and interior components. Its use contributes to weight reduction, which enhances vehicle speed and fuel efficiency. Sports cars and racing vehicles often feature extensive carbon fiber use for this reason. The ability to reduce weight without sacrificing safety or performance is a key driver for its adoption in this industry.

Beyond performance vehicles, carbon fiber is increasingly being used in mainstream automotive production. As manufacturers strive to meet stringent fuel efficiency standards, the integration of carbon fiber components offers a strategic advantage. The aesthetic appeal of carbon fiber also plays a role, as it allows for the creation of visually striking vehicle designs that stand out in the marketplace. This dual role of enhancing both performance and design underscores carbon fiber's value in automotive innovation.

Aerospace Industry

The aerospace industry was one of the first to adopt carbon fiber, using it in the construction of aircraft components like wings, fuselages, and propellers. The weight savings lead to significant fuel efficiency improvements, making it a staple in both commercial and military aviation. The ability to reduce weight without compromising structural integrity is critical in aerospace, where performance and safety are paramount.

In addition to commercial aviation, carbon fiber is also used in space exploration. Satellites and spacecraft benefit from the reduced weight and increased durability that carbon fiber provides. As the aerospace industry continues to push the boundaries of exploration and innovation, carbon fiber remains a key material in achieving new milestones in performance and efficiency. Its contribution to reducing fuel costs and enabling more ambitious missions highlights its strategic importance in aerospace applications.

Sports Equipment

Athletic gear such as bicycles, tennis rackets, and golf clubs often incorporate carbon fiber due to its strength and light weight. This not only improves performance but also enhances user comfort, as lighter equipment is easier to handle. Athletes benefit from the competitive edge that carbon fiber equipment provides, allowing them to achieve higher performance levels and reduce the risk of fatigue.

Moreover, carbon fiber's ability to absorb vibrations and shocks makes it ideal for sports equipment. This property enhances the comfort and control experienced by athletes, contributing to better performance outcomes. The adoption of carbon fiber in sports equipment represents a significant advancement in the pursuit of excellence, enabling athletes to push their limits and redefine what is possible in their respective fields.

Consumer Electronics

Carbon fiber's sleek appearance and lightweight properties have made it a popular choice in consumer electronics. Laptops, smartphones, and even musical instruments are incorporating carbon fiber to enhance durability and portability. The use of carbon fiber allows manufacturers to create thinner, lighter, and more durable products that meet the demands of modern consumers.

In addition to its functional benefits, carbon fiber adds a premium aesthetic quality to consumer electronics. The material's distinct look and feel set products apart in a competitive market, appealing to consumers who value both performance and style. As technology continues to evolve, the role of carbon fiber in consumer electronics is likely to expand, offering new possibilities for innovation and design.

The Future of Carbon Fiber

As technology advances, the applications and production methods of carbon fiber are expected to evolve. Researchers are working on more cost-effective production techniques and recycling methods to make carbon fiber a more sustainable option. As these advancements occur, we can expect carbon fiber to become even more prevalent in industries where traditional materials once dominated. The potential for new applications and improved production processes promises a dynamic future for carbon fiber.

Furthermore, the future of carbon fiber may involve the development of hybrid materials that combine its properties with those of other advanced materials. Such innovations could lead to the creation of next-generation composites that offer unparalleled performance and versatility. The continuous exploration of carbon fiber's potential reflects the broader trends in material science, where innovation is driven by the need for efficiency, sustainability, and enhanced capabilities.

Conclusion

Carbon fiber offers a compelling combination of strength, lightness, and resistance to corrosion, making it an attractive alternative to traditional materials like steel and aluminum. While it does come with a higher cost, the benefits often outweigh the investment in applications where performance and efficiency are paramount. As industries become increasingly focused on innovation and sustainability, carbon fiber's role is set to grow, offering new opportunities for material advancement.

As the production processes improve and costs decrease, it's likely that carbon fiber will continue to replace traditional materials in an increasing number of applications. Understanding its advantages and limitations is crucial for industries looking to innovate and improve their products. With its unique properties and potential for future development, carbon fiber is poised to play a pivotal role in shaping the future of material science and engineering.

In conclusion, whether you're in the automotive, aerospace, or consumer electronics industry, carbon fiber presents a forward-thinking option that could redefine performance standards and contribute to a more efficient future. The ongoing advancements in carbon fiber technology promise exciting possibilities, ensuring its continued relevance and impact across diverse fields.