Welcome to Mondince Bike - A well-known factory specialized in produce carbon bike frame and other parts since 2007.

How to Choose Carbon Fiber Sheets

When it comes to selecting carbon fiber sheets, it's essential to understand the nuances of this advanced material. Whether you're a hobbyist, a professional engineer, or someone exploring new materials for a project, choosing the right carbon fiber sheets can significantly impact your end results. In this guide, we'll delve into the key considerations to help you make an informed decision.

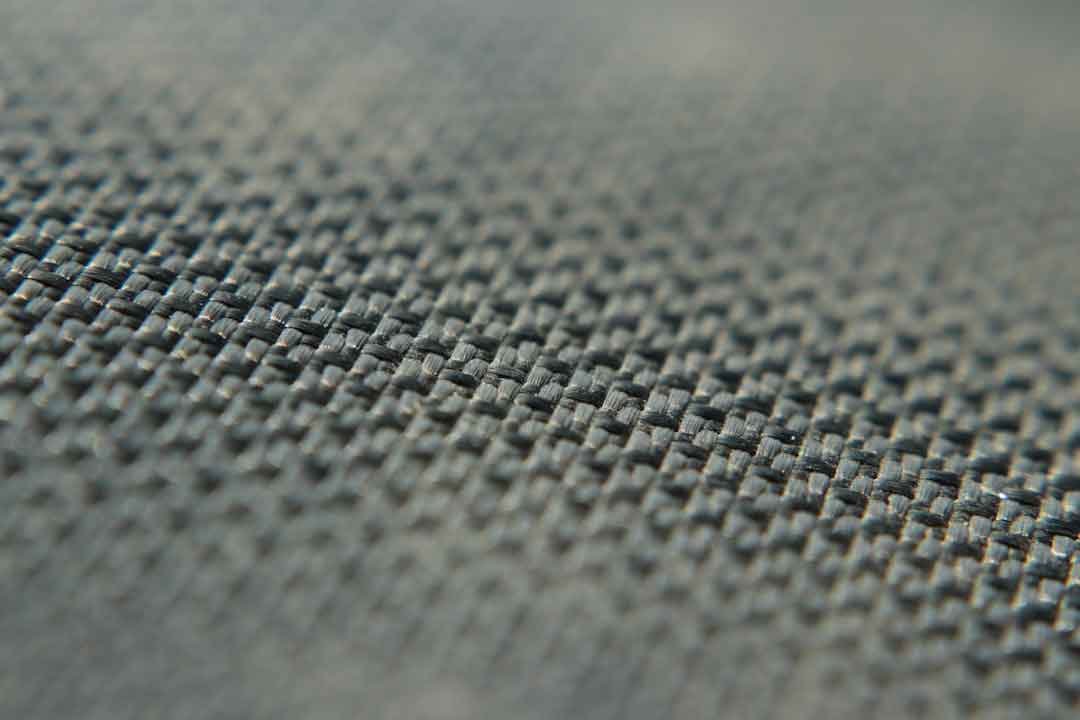

Carbon fiber is renowned for its high strength-to-weight ratio and rigidity. This composite material is composed of thin, strong crystalline filaments of carbon, which can be woven into a fabric and combined with other materials like epoxy to form a wide variety of products, including sheets, rolls, and mats.

Key Benefits of Carbon Fiber

- Strength and Durability: Carbon fiber is five times stronger than steel and twice as stiff, yet lighter, making it an ideal choice for various applications.

- Lightweight: Its lightweight nature makes it perfect for applications where reducing weight is critical without compromising strength.

- Corrosion Resistance: Unlike metals, carbon fiber does not rust or corrode, offering longevity and reliability in harsh environments.

- Temperature Tolerance: Carbon fiber can withstand high temperatures, which makes it suitable for various industrial applications.

Types of Carbon Fiber Sheets

When searching for carbon fiber material for sale, you'll encounter different types. Understanding these variations can help you decide which is best suited for your needs.

Prepreg Carbon Fiber Sheets

Prepreg carbon fiber sheets come pre-impregnated with a resin system, which makes them easy to mold and cure. They are popular in industries where precision and high performance are necessary, such as aerospace and automotive.

Laminated Carbon Fiber Sheets

Laminated sheets are created by stacking layers of carbon fiber cloth and bonding them with resin. This method allows for customization in terms of thickness and strength, suitable for structural applications.

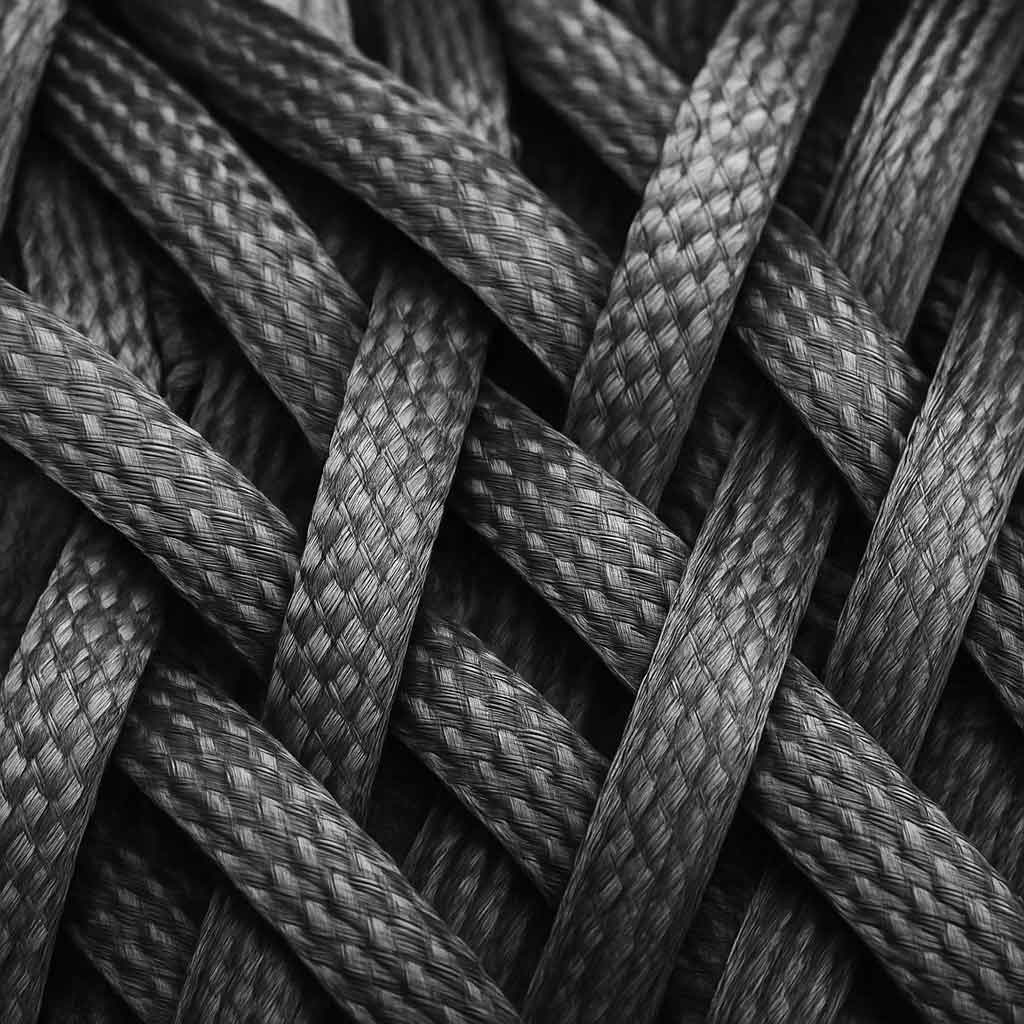

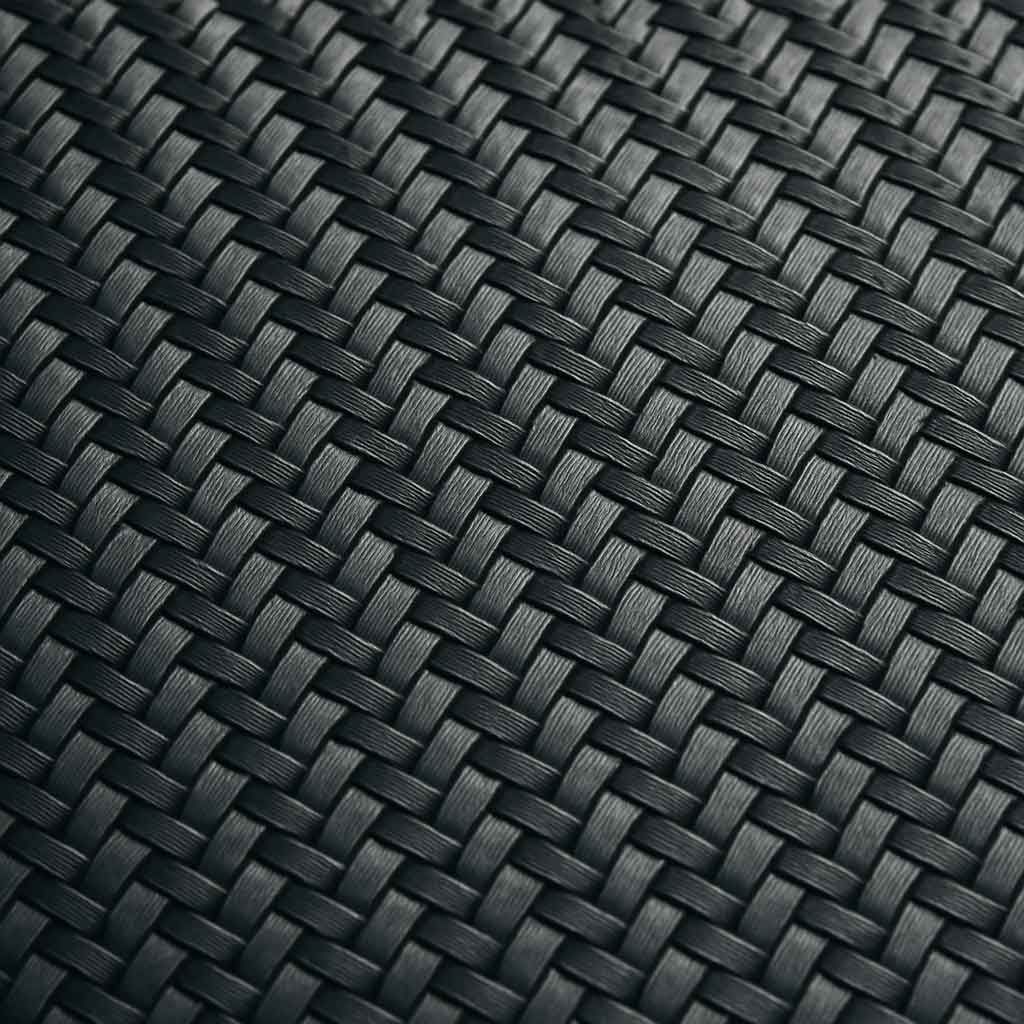

3K Twill Weave

The 3K twill weave is one of the most common weaves for carbon fiber fabric cloth. It provides a balance of strength and flexibility and is often used for aesthetic applications due to its attractive pattern.

Choosing the Right Carbon Fiber Sheet

Selecting the appropriate carbon fiber sheet depends on several factors, including your intended application, budget, and specific material properties.

Consider Your Application

- Structural Applications: If your project requires structural support, opt for laminated sheets, as they offer enhanced rigidity and strength.

- Aesthetic Applications: For projects where appearance is key, such as in consumer products or automotive interiors, 3K twill weave sheets are ideal.

- Heat Resistance: For applications involving high temperatures, ensure the carbon fiber sheet you choose can withstand the required thermal conditions.

Budget Considerations

The price of carbon fiber can vary significantly based on its type and quality. When evaluating carbon fiber price, consider the sheet's thickness, weave pattern, and resin system, as these factors can influence cost. Generally, prepreg sheets are more expensive due to their ease of use and precision.

Sourcing Carbon Fiber Sheets

Knowing where to buy carbon fiber sheets is crucial. Look for reputable suppliers with positive reviews and a track record of delivering quality materials. Consider suppliers that offer a range of products, including carbon fiber cloth roll, carbon fabric roll, and other related materials.

by Akshay Krishna (https://unsplash.com/@qwertywerty18)

Common Uses of Carbon Fiber Sheets

Carbon fiber sheets are incredibly versatile and used across multiple industries. Here are some common applications:

- Automotive: Used for body panels, interior trim, and engine components to reduce weight and improve fuel efficiency.

- Aerospace: Essential for aircraft parts due to their lightweight and high-strength properties.

- Sports Equipment: Used in making lightweight and durable sports gear such as bicycles, golf clubs, and racquets.

- Construction: Employed in structures requiring added strength without additional weight.

Maintenance and Care

While carbon fiber is durable, proper maintenance ensures longevity and optimal performance. Regularly inspect for any damage, especially in high-stress applications, and clean with mild soap and water to maintain its appearance.

Conclusion

Choosing the right carbon fiber sheets involves understanding your specific needs and the properties of different carbon fiber materials. Consider the type of application, budget, and where to buy carbon fiber to ensure you select the best product for your project. With its strength, lightweight nature, and versatility, carbon fiber is a superior choice for numerous applications.

By taking the time to research and understand the options available, you can confidently make a decision that will contribute to the success and performance of your projects. Happy crafting!