Welcome to Mondince Bike - A well-known factory specialized in produce carbon bike frame and other parts since 2007.

Carbon Fiber Sheets: Strength and Durability

Carbon fiber sheets have become a staple in industries that require high-strength, lightweight materials. These sheets are renowned for their superior strength-to-weight ratio, making them ideal for a variety of applications, from automotive to aerospace and beyond. In this article, we'll delve into what makes carbon fiber sheets so strong and durable, explore their numerous applications, and guide you on where to buy carbon fiber materials.

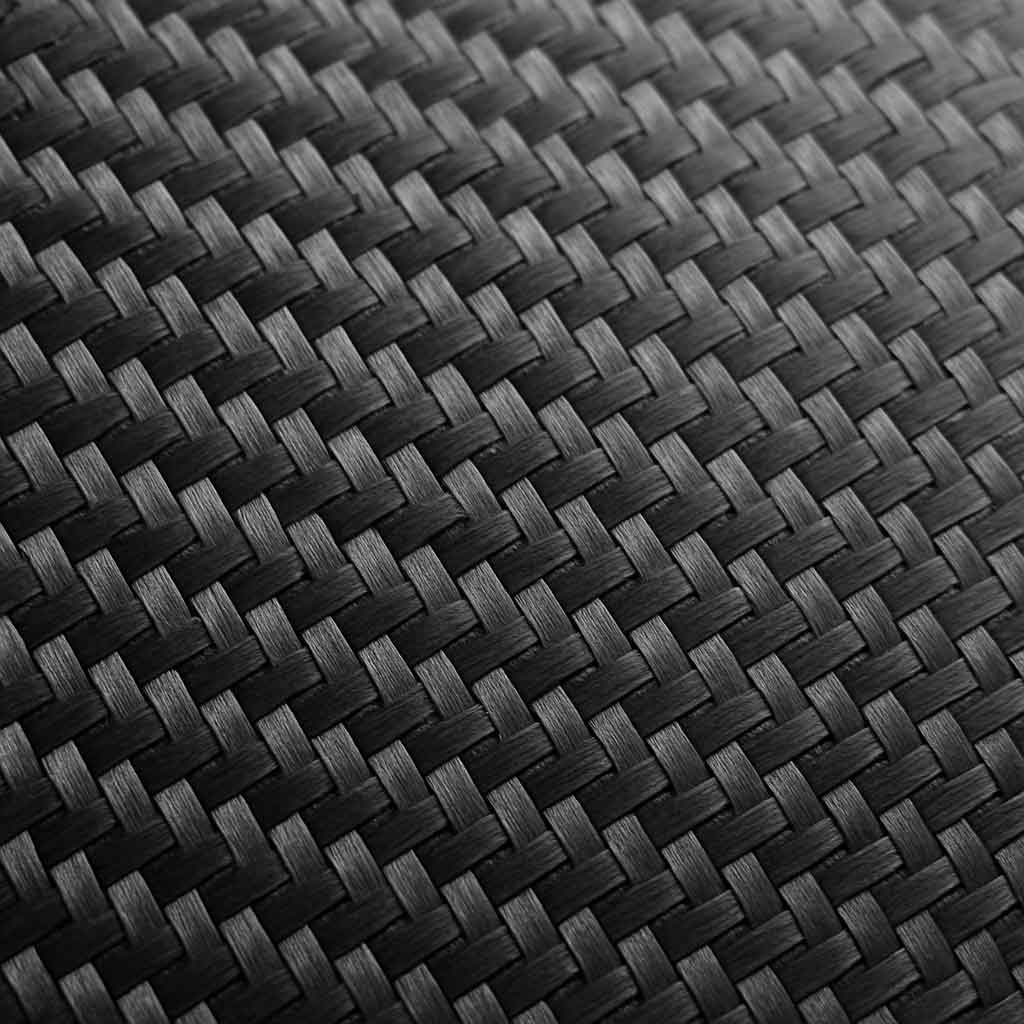

Carbon fiber sheets are made from carbon atoms bonded together to form a long chain. This material is woven into fabric and then laid over a mold and coated with resin to form a rigid sheet. The result is a product that is incredibly strong and lightweight.

Composition and Manufacturing

The creation of carbon fiber sheets begins with the formation of carbon atoms in a crystalline structure. These atoms are then spun into fibers that are as thin as a strand of human hair. The fibers are woven into fabric, which is laid over molds to achieve the desired shape. When the fabric is coated with resin, it hardens to form a rigid sheet, which possesses the unique combination of strength and light weight.

Crystalline Structure

The key to carbon fiber's strength lies in its crystalline structure. Carbon atoms are bonded in a way that aligns them into long chains, which are then twisted together. This configuration allows the material to resist stretching and bending, contributing to its remarkable strength.

Weaving Techniques

The weaving of carbon fibers into fabric is a meticulous process that determines the final product's properties. Different weaving patterns affect the flexibility, strength, and thickness of the resulting sheets. Manufacturers may use plain, twill, or satin weaves depending on the intended application of the carbon fiber sheet.

Resin Application

Applying resin is a critical step in manufacturing carbon fiber sheets. The resin binds the fibers, providing rigidity and protection against environmental factors. Epoxy resins are commonly used due to their strong bonding properties and resistance to heat and chemicals. Once cured, the resin-coated fabric becomes a robust and durable sheet.

Why Choose Carbon Fiber Sheets?

Strength and Lightweight

One of the primary reasons for the widespread use of carbon fiber sheets is their strength. Carbon fiber is five times stronger than steel and twice as stiff, yet it is much lighter. This makes it an excellent choice for applications where weight savings are crucial.

Superior Strength

The superior strength of carbon fiber sheets is derived from the atomic structure of carbon. This strength enables them to withstand significant stress without deforming. In industries like aerospace and automotive, this property is vital for components that must endure high forces while maintaining integrity.

Weight Reduction

Weight reduction is a critical factor in many industries, and carbon fiber excels in this regard. Its lightweight nature allows manufacturers to create products that are not only strong but also efficient. In automotive applications, lighter vehicles mean improved fuel economy and performance.

Energy Efficiency

The combination of strength and lightweight properties of carbon fiber contributes to energy efficiency. Whether in vehicles, aircraft, or sporting equipment, the reduced weight means less energy is required for movement. This efficiency translates to cost savings and a reduced environmental impact.

Durability

Carbon fiber sheets are also known for their durability. They can withstand high temperatures and resist corrosion, making them ideal for challenging environments. This durability ensures that products made from carbon fiber last longer, reducing the need for frequent replacements.

Temperature Resistance

One of the significant advantages of carbon fiber is its ability to withstand extreme temperatures. This makes it suitable for applications in environments where other materials might fail. For example, in aerospace, components made from carbon fiber can endure the high temperatures encountered during flight.

Corrosion Resistance

Unlike metals, carbon fiber does not corrode, which makes it an excellent choice for applications exposed to moisture or chemicals. This property is particularly beneficial in marine and chemical processing industries, where durability is crucial.

Longevity

The combination of temperature and corrosion resistance ensures that carbon fiber products have a long lifespan. This longevity reduces the need for frequent replacements and maintenance, resulting in cost savings over time. Products maintain their performance and appearance even after years of use.

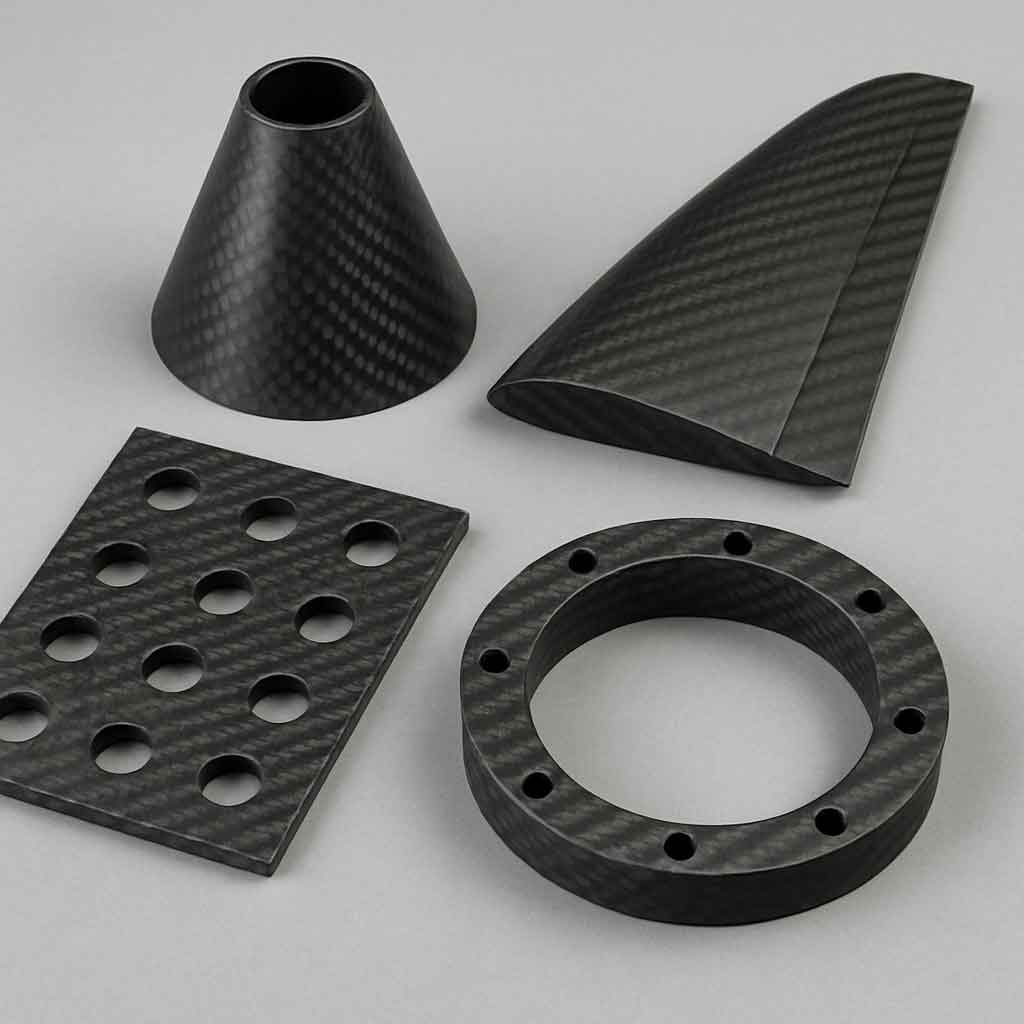

Versatility

Carbon fiber sheets can be tailored to meet specific needs. They can be cut into various shapes and sizes, making them versatile for different applications. Whether you need a carbon fiber mat, a carbon fiber cloth roll, or a carbon fiber sheet, there's a solution to fit your requirements.

Customization

One of the standout features of carbon fiber sheets is their ability to be customized. Manufacturers can tailor the thickness, weave pattern, and resin type to meet specific requirements. This customization ensures that the material is perfectly suited for its intended application.

Wide Range of Applications

The versatility of carbon fiber allows it to be used in an array of industries. From high-performance automotive parts to lightweight sports equipment, the possibilities are nearly endless. This adaptability is one of the reasons for its widespread adoption across different fields.

Innovative Designs

The flexibility of carbon fiber sheets enables the creation of innovative designs that were previously impossible with traditional materials. Designers and engineers can explore new shapes and structures, pushing the boundaries of what's achievable in product development.

Applications of Carbon Fiber Sheets

Automotive Industry

In the automotive industry, carbon fiber sheets are used to make lightweight, high-performance parts. Car manufacturers use carbon fiber to reduce the weight of vehicles, which improves fuel efficiency and performance. Components like hoods, roofs, and body panels benefit from carbon fiber's strength and light weight.

Enhanced Performance

The use of carbon fiber in automotive parts significantly enhances vehicle performance. Reduced weight leads to faster acceleration, improved handling, and increased efficiency. Sports cars, in particular, benefit from carbon fiber components that offer a competitive edge on the track.

Fuel Efficiency

With the growing emphasis on sustainability, fuel efficiency is a top priority for car manufacturers. Lighter vehicles require less energy to move, which translates to lower fuel consumption and reduced emissions. Carbon fiber plays a crucial role in achieving these environmental goals.

Safety Improvements

Despite its lightweight nature, carbon fiber provides excellent impact resistance. In the event of a collision, carbon fiber components can absorb and dissipate energy effectively, enhancing vehicle safety. This property makes carbon fiber a valuable material for safety-critical parts like crash structures.

Aerospace and Aviation

In aerospace, the strength and light weight of carbon fiber sheets make them ideal for aircraft parts. They are used in the construction of wings, fuselages, and other critical components. The use of carbon fiber helps improve fuel efficiency and allows for more extended flight ranges.

Structural Integrity

The aerospace industry demands materials that offer structural integrity without compromising weight. Carbon fiber sheets provide the perfect solution, allowing aircraft to maintain strength while reducing overall weight. This balance is essential for ensuring safety and performance.

Extended Flight Ranges

By reducing the weight of aircraft, carbon fiber enables longer flight ranges and increased payload capacity. Airlines can operate more efficient routes, saving fuel and reducing costs. This capability is particularly valuable in long-haul and cargo operations.

Environmental Impact

The environmental benefits of carbon fiber extend to the aerospace industry as well. Lighter aircraft produce fewer emissions, contributing to more sustainable aviation practices. As the industry seeks to reduce its carbon footprint, carbon fiber plays a pivotal role in achieving these objectives.

Sports and Recreation

Carbon fiber sheets are also popular in the sports and recreation industry. They are used to make equipment like bicycles, tennis rackets, and golf clubs. The lightweight nature of carbon fiber improves performance and reduces fatigue for athletes.

Performance Enhancement

Athletes rely on equipment that maximizes performance, and carbon fiber delivers on this front. Whether it's a tennis racket that provides better ball control or a bicycle frame that offers superior speed, carbon fiber components enhance athletic abilities.

Fatigue Reduction

The reduced weight of carbon fiber sports equipment translates to less strain on athletes. This reduction in fatigue allows athletes to perform at their best for longer durations, whether on the court or the field. The result is improved performance and a competitive advantage.

Custom Equipment

Carbon fiber's versatility allows for the creation of custom sports equipment tailored to individual athletes. Manufacturers can adjust the stiffness, weight, and shape to match specific preferences, leading to highly personalized gear that meets precise needs.

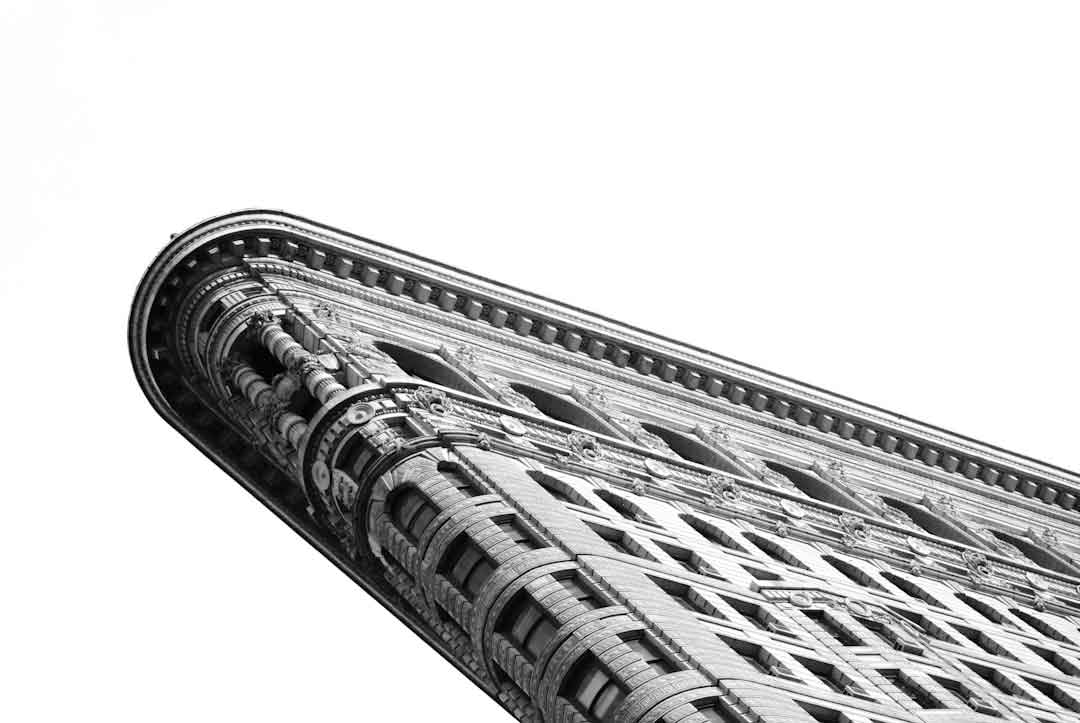

Construction and Architecture

In construction, carbon fiber sheets are used for reinforcing structures. They provide additional strength without adding significant weight, making them ideal for retrofitting and strengthening existing structures.

Structural Reinforcement

The construction industry utilizes carbon fiber sheets to reinforce existing structures, enhancing their strength and stability. This reinforcement is particularly valuable in earthquake-prone areas where buildings must withstand seismic forces.

Retrofitting Solutions

Carbon fiber offers efficient solutions for retrofitting aging infrastructure. By adding carbon fiber sheets, engineers can improve the load-bearing capacity of bridges, buildings, and other structures without significant weight increase. This approach extends the lifespan of infrastructure and improves safety.

Innovative Architectural Designs

Architects are increasingly incorporating carbon fiber into their designs for its unique properties. The material's flexibility and aesthetic appeal allow for the creation of innovative and visually striking structures. Carbon fiber can be molded into intricate shapes, offering endless possibilities for creative architectural projects.

Where to Buy Carbon Fiber Materials

If you're looking to purchase carbon fiber sheets or materials, there are several options available. You can find carbon fiber fabric cloth, carbon fabric rolls, and carbon fiber sheets for sale online and in specialized stores.

Online Retailers

Many online retailers offer a wide range of carbon fiber products. Websites that specialize in composites materials often have a variety of carbon fiber sheets, cloths, and rolls available for purchase. Some popular online platforms include:

eBay

On eBay, you'll find a diverse selection of carbon fiber materials, including cloths and sheets. The platform allows you to compare prices and read reviews from other buyers, ensuring you make an informed decision. Whether you're a DIY enthusiast or a professional, eBay offers options to suit your needs.

Amazon

Amazon provides an extensive range of carbon fiber sheets and fabrics at various price points. With detailed product descriptions and customer reviews, you can choose the right product with confidence. The convenience of home delivery and competitive pricing makes Amazon a popular choice for carbon fiber purchases.

Specialized Composite Material Websites

For those seeking high-quality carbon fiber supplies, specialized composite material websites are an excellent resource. These sites offer a wide array of products with detailed specifications, ensuring you find the exact material needed for your project. Many of these sites also provide technical support and guidance for selecting the right product.

Local Suppliers

If you prefer to see the materials in person before purchasing, you can find local suppliers who specialize in composite materials. Check with local hardware stores or specialty shops to see if they stock carbon fiber supplies.

In-Store Experience

Visiting a local supplier allows you to physically inspect the materials, assessing their quality and suitability for your project. Knowledgeable staff can provide valuable insights and recommendations based on your specific requirements. This personal interaction can be beneficial, especially for first-time buyers.

Supporting Local Businesses

Purchasing from local suppliers supports the local economy and fosters relationships with businesses in your community. Many local stores offer competitive pricing and may provide additional services like custom cutting or fabrication. Building a relationship with a local supplier can lead to long-term benefits for your projects.

Networking Opportunities

Local suppliers often serve as hubs for professionals in the industry, providing opportunities to network and collaborate with others in your field. By engaging with local suppliers, you can gain insights into industry trends and connect with potential collaborators for future projects.

Pricing

by Maya Alexa G. Romero (https://unsplash.com/@mayulec)

The cost of carbon fiber sheets can vary depending on the quality and specifications. Generally, carbon fiber is more expensive than traditional materials like steel or aluminum due to its advanced manufacturing process. However, its benefits often outweigh the initial cost, especially in performance-critical applications.

Cost Considerations

When considering the cost of carbon fiber, it's essential to evaluate the specific needs of your project. While the initial investment may be higher, the long-term benefits of reduced weight, increased strength, and durability can lead to cost savings over time. For many applications, these advantages justify the higher price point.

Price Ranges

The price of carbon fiber sheets can range from $10 to $50 per square foot, depending on factors like thickness, quality, and weave pattern. High-quality sheets with advanced properties will naturally be more expensive, but they offer superior performance and longevity.

Value Proposition

Ultimately, the value of carbon fiber lies in its ability to deliver exceptional performance and longevity. For industries where weight, strength, and durability are critical, the investment in carbon fiber materials can lead to significant returns in terms of efficiency, safety, and innovation.

Conclusion

Carbon fiber sheets are a game-changer in industries that require materials with exceptional strength and minimal weight. Their durability and versatility make them suitable for a wide range of applications, from automotive and aerospace to sports and construction. Whether you're looking for carbon fiber cloth, rolls, or sheets, there are plenty of options available for purchase. With the right supplier, you can find the perfect carbon fiber material to meet your needs.

By understanding the benefits and applications of carbon fiber sheets, you can make informed decisions about incorporating this advanced material into your projects. Whether you're asking, "Where can I buy carbon fiber?" or "How much is carbon fiber?" this guide provides you with the knowledge to navigate the market and find the best carbon fiber solutions for your needs. Embrace the future of material science with carbon fiber and unlock new possibilities for innovation and performance.