Welcome to Mondince Bike - A well-known factory specialized in produce carbon bike frame and other parts since 2007.

Comparing Carbon Fiber Sheets to Alternatives

In the world of advanced materials, carbon fiber sheets stand out for their remarkable properties and versatility. Whether you're an engineer, designer, or hobbyist, understanding the benefits and drawbacks of carbon fiber sheets compared to other materials can help you make informed decisions for your projects. Carbon fiber sheets have gained immense popularity due to their unique characteristics, which make them suitable for a variety of high-performance applications. This article provides a comprehensive comparison, focusing on key aspects such as strength, weight, cost, and availability. By the end of this article, you’ll have a better grasp of where carbon fiber fits into the landscape of material choices and how it can potentially transform your projects.

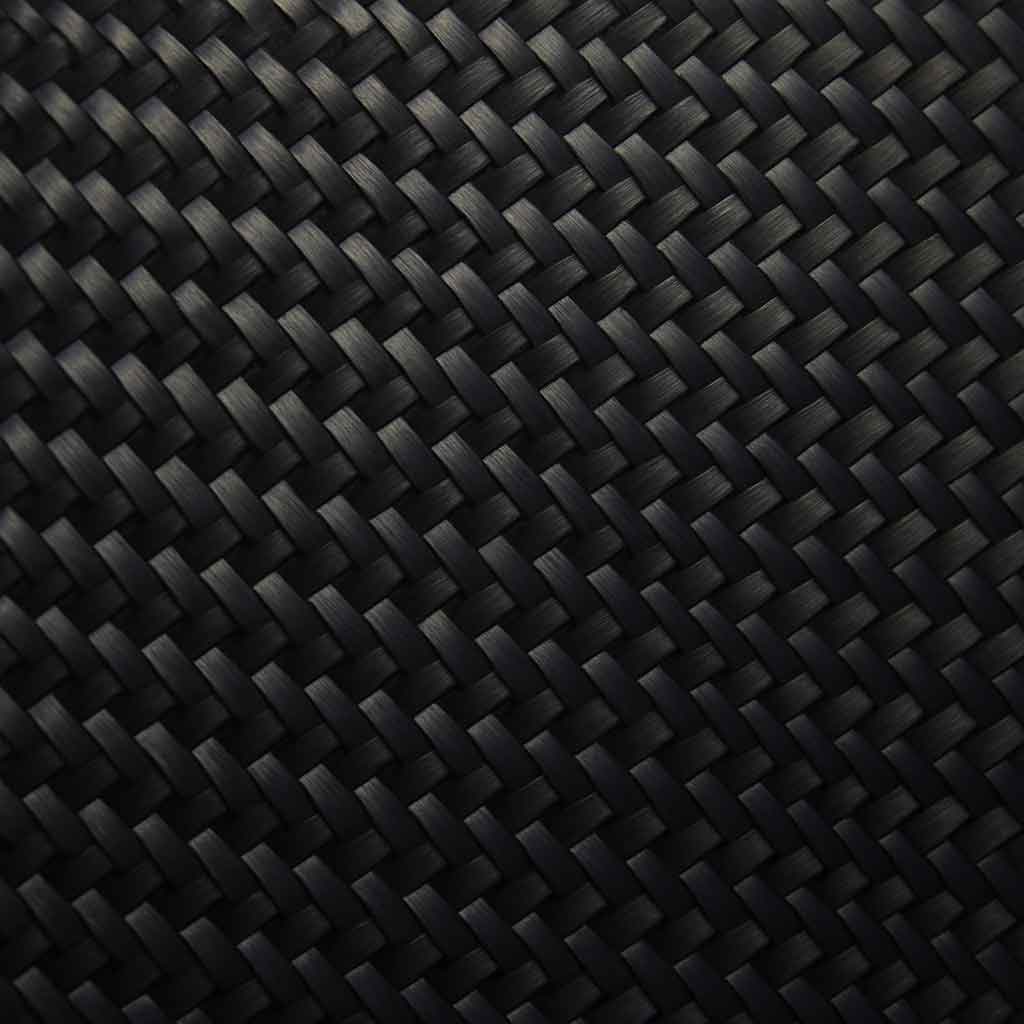

Carbon fiber is a material made of thin strands of carbon atoms tightly bonded in a crystal alignment. This structure grants carbon fiber its impressive strength-to-weight ratio, making it a popular choice in industries ranging from aerospace to automotive. The process of creating carbon fiber involves weaving the strands into a fabric, which is then combined with a polymer to form a composite material. This complex process is a key factor in the material's performance capabilities and its premium pricing. Understanding the fundamental composition and manufacturing of carbon fiber is crucial to appreciating its unique qualities and applications.

Key Characteristics of Carbon Fiber

- Strength and Durability: Carbon fiber is known for its high tensile strength and durability, making it ideal for applications requiring long-lasting materials. This strength is derived from the carbon atoms' alignment, which allows the material to withstand significant stress without deforming. The durability of carbon fiber also means it can endure harsh conditions, including temperature extremes and mechanical stress, without losing its integrity.

- Lightweight: Despite its strength, carbon fiber is incredibly lightweight, which is why it's often used in applications where reducing weight is crucial. The low density of carbon fiber makes it an excellent substitute for heavier materials like steel, offering similar or superior strength without the added weight. This characteristic is particularly valuable in industries such as aerospace and automotive, where reducing weight can lead to better fuel efficiency and performance.

- Corrosion Resistance: Unlike metals, carbon fiber does not rust or corrode, making it suitable for use in challenging environments. This resistance to corrosion extends the lifespan of components made from carbon fiber, reducing maintenance costs and downtime. Additionally, carbon fiber's inert nature makes it an excellent choice for applications exposed to chemicals or saltwater, where other materials might quickly degrade.

Alternatives to Carbon Fiber Sheets

While carbon fiber sheets offer many advantages, they are not the only option available. Here, we compare them to several alternatives, including fiberglass, aluminum, and steel. Each of these materials has its unique properties and is suited to different applications, depending on the specific needs and constraints of a project. By examining these alternatives, you can better assess the trade-offs and choose the most appropriate material for your needs.

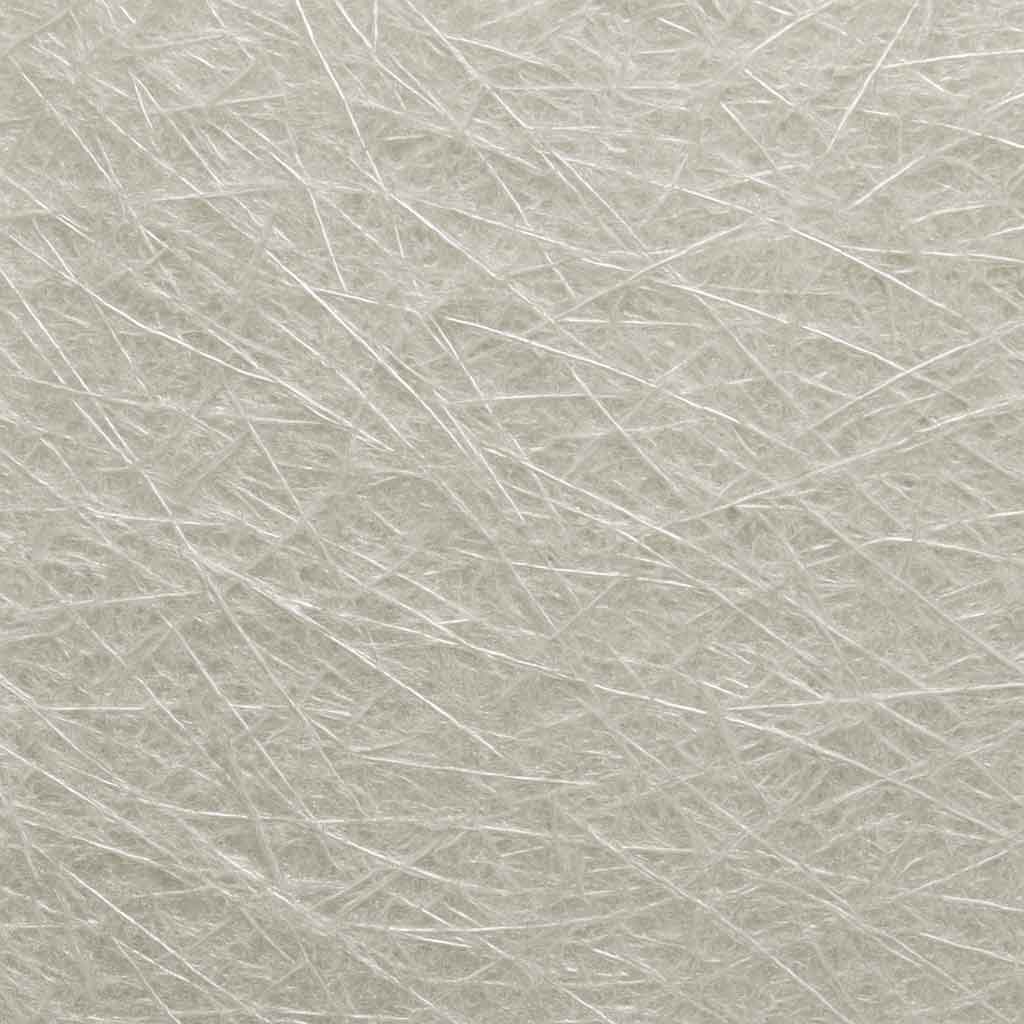

Fiberglass

Fiberglass is another composite material made from glass fibers embedded in a resin matrix. It shares some similarities with carbon fiber but differs in several key areas.

- Strength: Fiberglass is less strong than carbon fiber, which means it might not be suitable for high-performance applications. However, it still offers adequate strength for many general-purpose applications, making it a versatile option for less demanding projects. The strength of fiberglass is sufficient for various consumer products and some structural applications where the ultimate load is not a critical factor.

- Weight: Fiberglass is heavier than carbon fiber, which can be a disadvantage in weight-sensitive projects. The added weight can affect performance and efficiency, particularly in industries where every gram counts, such as aerospace and competitive sports. However, for applications where weight is less of a concern, fiberglass provides a cost-effective alternative.

- Cost: One of the main advantages of fiberglass is its lower cost, making it a more budget-friendly option for many applications. The affordability of fiberglass makes it accessible for a wide range of uses, from construction and automotive to recreational products. Its cost-effectiveness is a significant factor for projects with tight budgets or where the material is needed in large quantities.

Aluminum

Aluminum is a common metal used in many industries due to its strength, lightweight nature, and resistance to corrosion. Its versatility and relatively low cost make it a popular choice for many applications, from household goods to industrial components.

- Strength: While strong, aluminum cannot match the tensile strength of carbon fiber. However, aluminum's strength is sufficient for many applications, offering a good balance between performance and cost. It is particularly favored in applications where a combination of moderate strength and low weight is necessary.

- Weight: Aluminum is heavier than carbon fiber but lighter than steel, making it a good middle-ground for weight and strength. This characteristic makes aluminum ideal for industries like automotive and aerospace, where reducing weight without compromising strength is crucial. Its lightweight nature also contributes to improved fuel efficiency and handling in vehicles.

- Cost: Generally, aluminum is more affordable than carbon fiber, which can be a significant factor in material selection. The lower cost of aluminum makes it an attractive option for projects with budget constraints, offering a reasonable compromise between performance and price. Its widespread availability and recyclability also contribute to its economic appeal.

Steel

Steel is known for its exceptional strength and durability, often used in applications where material failure is not an option. Its robustness and reliability make it a staple material in construction, manufacturing, and infrastructure.

- Strength: Steel is stronger than both aluminum and fiberglass, but carbon fiber can outperform steel in tensile strength. Steel's compressive and impact strength, however, make it ideal for structural applications where these properties are paramount. Its ability to withstand heavy loads and resist deformation under stress is unmatched by many materials.

- Weight: Steel is significantly heavier, which can be a drawback for projects where weight reduction is critical. The high density of steel can impact performance and efficiency, particularly in applications requiring mobility or energy conservation. However, in scenarios where stability and strength are prioritized over weight, steel remains an unmatched option.

- Cost: Steel is typically less expensive than carbon fiber, making it a cost-effective option for many applications. Its affordability, combined with its strength, makes steel an ideal choice for large-scale projects and industries where budgetary constraints are a primary concern. The ability to recycle steel also adds to its economic and environmental benefits.

Cost Considerations

The cost of carbon fiber sheets can vary widely based on factors such as manufacturing processes, quality, and supplier. Understanding these costs is crucial for budgeting and project planning. The financial aspect of choosing carbon fiber over other materials often requires a careful evaluation of long-term benefits versus upfront costs.

How Much Does Carbon Fiber Cost?

The price of carbon fiber sheets can range from $10 to $50 per square foot, depending on the quality and specifications. Factors such as thickness, weave pattern, and finish can also affect pricing. Higher-grade carbon fiber with specialized weaves and finishes can significantly increase costs, but they also offer enhanced performance features that might justify the investment for certain applications.

Where to Buy Carbon Fiber Sheets

Carbon fiber sheets can be purchased from specialized suppliers, online marketplaces, and composite material retailers. When buying, it's important to consider the supplier's reputation, product quality, and customer reviews. Established suppliers often provide better quality assurance and support, which can be crucial for projects that demand high precision and reliability. Additionally, buying from reputable sources can reduce the risk of counterfeit products, ensuring you receive genuine carbon fiber material.

Applications of Carbon Fiber Sheets

Carbon fiber sheets are utilized in a variety of industries due to their unique properties. Here are some common applications:

- Aerospace: Carbon fiber is used extensively in aircraft components due to its strength and lightweight nature, helping improve fuel efficiency. It allows for the construction of lighter, more fuel-efficient aircraft without compromising safety or performance. The aerospace industry continues to explore new applications for carbon fiber, aiming to further enhance the efficiency and capabilities of modern aircraft.

- Automotive: In the automotive sector, carbon fiber is used for body panels, interiors, and performance parts to reduce weight and enhance vehicle performance. Its use in high-performance and luxury vehicles is particularly notable, where the benefits of weight reduction translate into improved speed, handling, and fuel efficiency. As technology advances, carbon fiber is increasingly being adopted in mainstream automotive manufacturing as well.

- Sports Equipment: High-performance sports gear, such as bicycles, tennis rackets, and golf clubs, often incorporate carbon fiber for its strength and lightweight benefits. Athletes benefit from the reduced weight and increased strength of their equipment, which can enhance performance and reduce fatigue. The sports industry continues to innovate with carbon fiber, creating more advanced equipment that offers competitive advantages.

- Construction: In the construction industry, carbon fiber sheets are used to reinforce structures and improve seismic performance. The material's strength and lightweight properties make it ideal for retrofitting buildings and bridges, enhancing their ability to withstand earthquakes and other stresses. Its use in construction is expanding as engineers and architects recognize the benefits of incorporating advanced materials into modern infrastructure.

Environmental Considerations

While carbon fiber offers many advantages, it's important to consider its environmental impact. The production process is energy-intensive, and recycling options for carbon fiber are still limited. Efforts to improve the sustainability of carbon fiber production are ongoing, with researchers exploring methods to reduce energy consumption and develop recycling technologies. However, ongoing research aims to develop more sustainable methods of production and recycling. These advancements could potentially lower the environmental footprint of carbon fiber, making it an even more attractive option for industries focused on sustainability.

Conclusion

by Bennie Bates (https://unsplash.com/@bennieray)

In summary, carbon fiber sheets offer a compelling combination of strength, lightweight properties, and durability, making them suitable for a range of applications. However, cost and environmental concerns are important factors to consider when choosing materials. By understanding the strengths and weaknesses of carbon fiber compared to alternatives like fiberglass, aluminum, and steel, you can make informed decisions for your projects. Whether you're looking to improve performance, reduce weight, or explore innovative applications, carbon fiber sheets remain a valuable option in the world of advanced materials. As technology and methods continue to evolve, the potential for carbon fiber to transform industries and applications only grows, promising exciting developments in the future of material science.